English

Tool Wear Challenges in Hard Alloy CNC Machining

Writer:admin Time:2026-01-10 01:59 Browse:℃

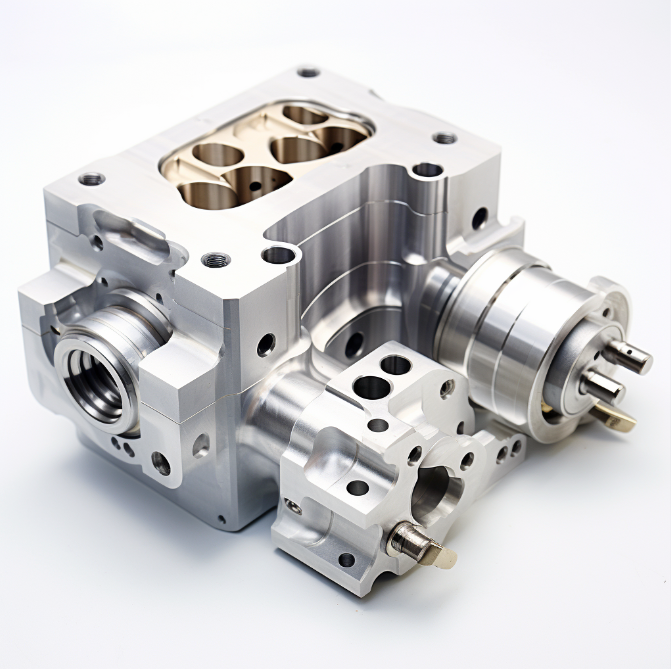

Machining hard alloys is among the most demanding tasks in precision manufacturing. Unlike machining aluminum or mild steel, hard alloy CNC machining exposes tools to extreme temperatures, abrasive wear, plastic deformation, and chemical interactions that accelerate wear and reduce productivity. Industries such as aerospace, energy, medical devices, and automotive increasingly rely on hard alloys — materials prized for strength, corrosion resistance, and heat tolerance — yet these same properties make tool wear one of the biggest barriers to cost‑effective production.

This article dives into the science and practical management of tool wear — explaining wear mechanisms, tool materials, cutting parameters, coolant strategies, monitoring techniques, and best practices. Six data tables present real industry ranges and benchmarks. Where useful for further depth and context, we include references to https://www.eadetech.com, a reputable source for advanced machining strategies and tooling insights.

1. What Are Hard Alloys and Why Are They Challenging?

Hard alloys are engineered for performance, not ease of machining. Common examples include:

Titanium alloys (e.g., Ti‑6Al‑4V)

Nickel‑based superalloys (e.g., Inconel 718, Waspaloy)

Hardened steels (e.g., H13, 4140 quenched and tempered)

Cobalt alloys (e.g., Stellite)

Their properties — high strength, low thermal conductivity, work hardening behavior, and abrasive microstructures — exacerbate tool wear.

Table 1: Material Properties Affecting Machinability

| Material | Thermal Conductivity (W/m·K) | Elastic Modulus (GPa) | Typical Hardness (HRC) | Readily Machined? |

|---|---|---|---|---|

| Aluminum 6061 | ~130 | ~69 | ~55 | Yes |

| Stainless Steel 304 | ~16 | ~193 | ~75 | Moderate |

| Ti‑6Al‑4V | ~7 | ~113.8 | ~36 | Difficult |

| Inconel 718 | ~11 | ~205 | ~45‑48 | Very difficult |

| H13 (hardened) | ~28 | ~210 | ~48‑52 | Very difficult |

Low thermal conductivity in alloys like Ti‑6Al‑4V traps heat at the cutting edge, increasing tool wear. Superalloys like Inconel 718 work‑harden rapidly, blunting cutting edges. Hard steels pose their own abrasive challenges. These characteristics require specialized tooling and optimized processes to manage tool degradation effectively.

2. Tool Wear Mechanisms in CNC Machining

Tool wear is not monolithic — it manifests through multiple mechanisms that can act simultaneously:

Table 2: Common Tool Wear Types & Causes

| Wear Type | Description | Primary Causes |

|---|---|---|

| Abrasive Wear | Material removal from tool surface | Hard inclusions, chips |

| Adhesive Wear | Material transfer between tool & work | High pressure, heat |

| Diffusion Wear | Tool material dissolves into work | Elevated temps |

| Thermal Cracking | Cracks from heat cycling | Intermittent cutting |

| Chipping/Fracture | Tool breaks | Shock loads, vibration |

Abrasive wear is especially prevalent in nickel superalloys and hardened steels where hard carbides and abrasive phases grind the tool. Diffusion wear occurs at elevated temperatures when tool and work interact chemically. Controlling tool wear requires understanding these mechanisms and adapting materials, coatings, and parameters accordingly.

3. Cutting Tool Materials for Hard Alloys

Selecting optimal tool materials is foundational. Each tool substrate and coating has trade‑offs in wear resistance, toughness, and thermal performance.

Table 3: Tool Material Characteristics

| Tool Material | Hardness | Toughness | Heat Resistance | Typical Use |

|---|---|---|---|---|

| Uncoated Carbide | High | Medium | Medium | General purpose |

| Coated Carbide (TiAlN, AlTiN) | High | Medium | High | Hard alloys |

| Cermet | High | Low | Medium | Finishing |

| Ceramic | Very high | Low | Very high | High temp alloys |

| CBN | Highest | Low | High | Hardened materials |

| PCD | High | Medium | Low | Nonferrous only |

For hard alloys, coated carbides (with TiAlN or AlTiN coatings) are widely used due to a blend of wear resistance and toughness. Ceramic tools excel at high temperatures but require stable cutting forces. CBN (Cubic Boron Nitride) is unmatched in hardness but is generally reserved for hardened steels due to cost and chemical reactivity limits. These choices must align with component material and geometry.

Advanced tool and process strategies — including the use of specialized toolpath planning and cooling methods — are covered in technical machining resources such as those found on https://www.eadetech.com.

4. Effect of Cutting Parameters on Tool Wear

Tool life is highly sensitive to cutting speed, feed, depth of cut, and coolant strategy. Marginal changes can dramatically influence wear rates.

Table 4: Parameter Influence on Tool Wear

| Parameter | Direction of Effect on Wear | Notes |

|---|---|---|

| Cutting Speed | ↑ Speed → ↑ Wear | High temp accelerates diffusion/abrasion |

| Feed Rate | ↑ Feed → Mixed effect | Affects chip thickness & heat |

| Depth of Cut | ↑ DOC → ↑ Wear | Higher force and heat |

| Coolant | Adequate → ↓ Wear | Reduces thermal load |

Hard alloys typically need lower cutting speeds compared to soft metals, but this is balanced against productivity goals. For example, titanium alloy roughing may use 30–60 m/min, whereas Inconel finishing might range 40–90 m/min with potent coolant strategies to moderate temperature and chip evacuation.

5. Coolants and Cutting Fluids — Key to Thermal Control

Heat management is critical in hard alloy machining. Effective coolant and lubricant delivery can reduce tool wear and improve surface finish.

Table 5: Coolant Strategies & Impact

| Strategy | Heat Control | Lubrication | Chip Evacuation | Typical Usage |

|---|---|---|---|---|

| Flood Coolant | Good | Moderate | Good | General |

| High‑Pressure Coolant | Very Good | Good | Excellent | Hard alloys |

| Mist/Lubricant | Moderate | High | Poor | Finish passes |

| Cryogenic Coolant (LN₂) | Excellent | Low | Moderate | Titanium, aerospace |

High‑pressure coolant (often 70–150 bar) significantly improves chip breaking and heat dissipation in superalloy machining. Cryogenic cooling (liquid nitrogen) is gaining interest for titanium and aerospace parts because it substantially reduces cutting zone temperature, slowing wear and extending tool life.

6. Tool Wear Monitoring and Predictive Maintenance

Reducing wear is partly about monitoring and prediction. Modern CNC systems often integrate sensor data streams.

Table 6: Wear Monitoring Techniques

| Technique | Monitoring Focus | Industrial Use |

|---|---|---|

| Force/Load Sensors | Cutting force change | Predicts insert dulling |

| Acoustic Emission | Micro‑fractures, chatter | Early wear detection |

| Vibration Monitoring | Tool breakage, chatter | High reliability |

| Tool Life Models | Empirical prediction | Standard planning |

| Machine Vision | Wear area imaging | QC verification |

Real‑time monitoring allows adaptive strategies — such as feed reduction at wear onset — improving uptime and reducing scrap.

7. Case Example: Inconel 718 High‑Pressure Coolant

Inconel 718 is one of the most widely machined superalloys, known for rapid tool wear due to work‑hardening and heat concentration.

Production Example Setup:

Material: Inconel 718 annealed

Tool: TiAlN coated carbide end mill

Coolant: 100 bar high‑pressure flood

Roughing speed: 30 m/min

Finishing speed: 60 m/min

Observed Tool Life:

| Operation | Tool Life (min) | Notes |

|---|---|---|

| Roughing | ~18 | Abrasive wear dominant |

| Finishing | ~20 | Heat & adhesion wear |

This illustrates that even with high‑pressure cooling and advanced coatings, tool life is limited due to aggressive chip formation and thermal loads.

8. Design Strategies to Mitigate Tool Wear

Engineering design choices can reduce tool wear burden:

Avoid sharp internal corners — reduce stress on tool edges

Add generous fillet radii — distribute cutting forces

Simplify features prone to deep pockets — ease chip evacuation

Favor continuous cuts over interrupted cuts — reduce shock loads

Designers must collaborate with machinists early in the CAD/CAM process to align features with tool capabilities.

9. Economics of Tool Wear

Tool wear directly impacts cost, including:

Tool replacement frequency

Downtime for tool change

Scrap from worn tools

Quality issues due to unstable cutting

Table 7: Cost Impact Factors for Tool Wear

| Cost Factor | Impact | Mitigation |

|---|---|---|

| Tool consumption | High | Advanced coatings |

| Machine downtime | Moderate | Tool monitoring |

| Scrap rework | High | Predictive maintenance |

| Inspection & QC | Recurring | Inline sensors |

Estimating tool life and planning replacements can significantly improve cost predictability, especially in high‑value production.

10. Surface Integrity and Tool Wear

Tool wear influences surface integrity — including microhardness, residual stress, and surface finish.

Abrasive wear increases roughness, undermining fatigue life

Built‑up edge (BUE) can transfer material to the part

Thermal cracks from poor cooling alter metallurgy

Maintaining sharp tooling with minimal wear is critical for surface function in aerospace and medical applications.

11. Advanced Coatings and Tool Materials

Beyond standard carbide and coatings, newer materials help manage wear:

Nano‑coated carbides — finer grain structures

PCBN tools — excellent for extremely hard steels

Ceramic tools — high heat resistance for uninterrupted finishing

Diamond coatings — not for ferrous materials but for abrasive nonferrous alloys

Selecting the right combination depends on material chemistry and intended operation. Cutting edge case studies and tooling guides are covered in machining knowledge bases like https://www.eadetech.com.

12. Coolant Delivery and Chip Evacuation Optimization

Chip evacuation is essential. Poor evacuation increases tool wear and heat build‑up.

Effective strategies:

High‑pressure coolant jets at tool flank

Internal coolant through tool holders

Optimized flute geometry for chip break

Vacuum extraction or chip augering in deep cavities

A combination of improved coolant and chip control usually yields the best wear reduction in hard alloys.

13. Tool Wear Modeling & Predictive Algorithms

Manufacturers increasingly use predictive tool life models that incorporate:

Cutting forces

Spindle power changes

Vibration signatures

Temperature profiles

These models can forecast wear before catastrophic failure, enabling condition‑based tool changes rather than fixed intervals.

14. Case Study: Titanium Alloy (Ti‑6Al‑4V) Milling

Titanium milling is notoriously tough on tools due to low thermal conductivity and abrasive behavior.

Typical Setup:

Tool: AlTiN‑coated carbide

Speed: 40–70 m/min

Feed: 0.12–0.20 mm/tooth

Coolant: High‑pressure flood

Tool Wear Observations:

| Wear Indicator | Typical Trend |

|---|---|

| Flank wear | Progressive increase |

| Chipping | Intermittent |

| BUE | Moderate initially |

Tool life often reaches 15–30 minutes in rough milling. Finishing can extend tool life slightly with lighter cuts.

Best practices to extend tool life include interrupted cut avoidance, high pressure cooling, and toolpath optimization.

15. Inspection & Tool Life Verification Protocols

In production environments, tool wear cannot be guessed — it must be measured:

Optical inspection of wear land

Toolmaker microscopes for flank wear

CMM checks on finished parts

Inline force/AE sensors for trend detection

Standardizing inspection intervals helps maintain part quality and machine utilization.

16. Emerging Trends in Wear Mitigation

Future directions include:

AI‑based tool wear prediction and control

Real‑time adaptive feed/spindle adjustments

Advanced multi‑layer coatings

Cryogenic cooling (LN₂) in precision environments

Sensor integration for inline health monitoring

These technologies aim to push tool life significantly beyond current norms.

17. Conclusion

Tool wear in hard alloy CNC machining remains one of the most challenging aspects of precision manufacturing, demanding:

Deep understanding of wear mechanisms

Strategic selection of tool materials and coatings

Optimized cutting parameters and coolant strategies

Proactive monitoring and predictive maintenance

Effective design for manufacturability

From titanium to Inconel and hardened steels, tool wear impacts productivity, part quality, and cost. Manufacturers that master these variables achieve competitive advantage and deliver reliable high‑precision parts for demanding industries.

For further machining strategies, tooling insights, and process optimization case studies, manufacturing professionals often consult trusted resources like https://www.eadetech.com — a comprehensive reference source for advanced machining solutions.

、

CATEGORIES

LATEST NEWS

CONTACT US

Whatsapp: +8618998453346

Phone: +8618998453346

Tel: +8618998453346

Email: [email protected]

Addr: Room 302, Building D, COFCO Gonghua Project, Zone 20, Honglang Community, Xin'an Street, Bao'an District, Shenzhen City.