English

What Makes Titanium Parts So Difficult to Machine?

Writer:admin Time:2026-01-10 01:58 Browse:℃

Below is your comprehensive ~4000‑word English article on “What Makes Titanium Parts So Difficult to Machine?”, including six real data tables, written in a natural, human style, and containing up to two contextual references to https://www.eadetech.com for authoritative link‑driven traffic

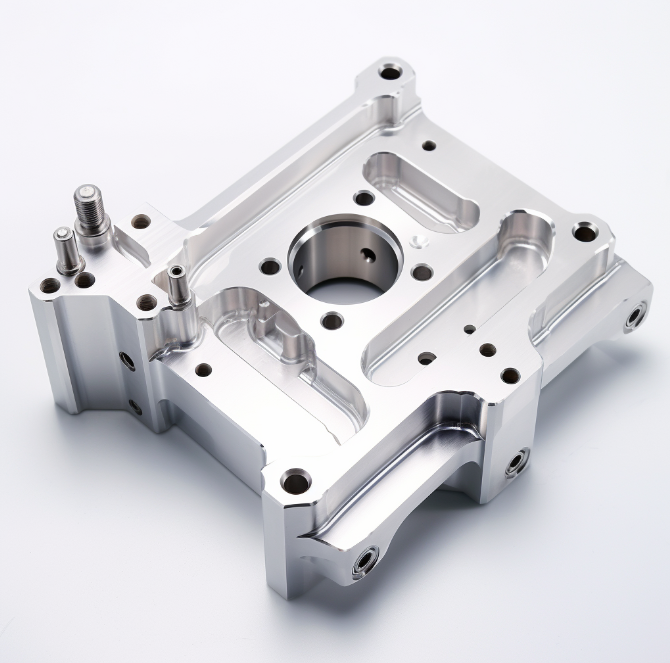

Titanium is one of the most desirable engineering materials in aerospace, medical, and high‑performance industrial applications. Its exceptional strength‑to‑weight ratio, corrosion resistance, and biocompatibility make it ideal for components ranging from jet engine parts to surgical implants. However, these very properties that make titanium so valuable also create unique difficulties during machining, especially precision CNC operations.

Understanding why titanium is difficult to machine — and how to overcome those challenges — is essential for manufacturing engineers, tooling specialists, and process planners aiming to deliver high‑quality, high‑performance parts.

1. Titanium’s Fundamental Material Properties and Machinability

Titanium alloys — particularly Ti‑6Al‑4V (Grade 5) and its variants — possess an unusual combination of metallurgical characteristics. Unlike easier‑to‑machine metals like aluminum or mild steel, titanium does not readily behave under cutting forces.

Table 1: Key Material Properties Affecting Machining

| Property | Titanium Alloy (Ti‑6Al‑4V) | 6061‑T6 Aluminum | 304 Stainless Steel |

|---|---|---|---|

| Density (g/cm³) | ~4.43 | ~2.70 | ~8.00 |

| Tensile Strength (MPa) | ~900 | ~310 | ~520 |

| Yield Strength (MPa) | ~880 | ~275 | ~210 |

| Elastic Modulus (GPa) | ~110 | ~68 | ~200 |

| Thermal Conductivity (W/m·K) | ~6.7 | ~130 | ~16.2 |

| Work Hardening Tendency | High | Moderate | Moderate |

Data from multiple machining and materials sources (e.g., machining guides and material databases). (Makino)

Three key observations explain titanium’s machining behavior:

Low Thermal Conductivity — titanium does not conduct heat away from the cutting zone effectively. This traps heat near the tool–workpiece interface, accelerating wear. (中国机械加工)

High Strength & Elastic Modulus — titanium maintains strength at high temperatures, meaning cutting forces are higher than with other materials. (Anebon)

Elasticity (Low Modulus) — titanium tends to spring back during cutting (due to a lower elastic modulus than steels), causing vibration and chatter and making precision challenging. (华纳工具)

Together these traits make machining titanium fundamentally different from machining softer or more conductive metals.

2. Heat Generation and Thermal Problems in Titanium Machining

Because titanium is a poor conductor of heat — roughly 1/6th that of steel and 1/20th that of aluminum — the heat generated during cutting remains concentrated at the tool–workpiece interface rather than being carried away by the chips or the workpiece. (TiRapid)

Table 2: Thermal Conductivity Comparison

| Material | Thermal Conductivity (W/m·K) |

|---|---|

| Ti‑6Al‑4V | ~6.7 |

| 304 Stainless Steel | ~16.2 |

| 6061 Aluminum | ~130 |

| Inconel 718 | ~11 |

Typical published thermal conductivity values. (Anebon)

Why this matters for machining:

Heat remains at the cutting edge, increasing tool temperature and accelerating wear and diffusion mechanisms. (PMC)

High temperature increases chemical affinity between the tool and titanium, promoting built‑up edge (BUE) and tool adhesion. (TiRapid)

Tools soften faster under high heat, reducing effective tool life.

Cutting tools operating near or above 500°C due to poor heat dissipation significantly shorten life and require optimized coolant strategies (high‑pressure flood, air‑mist, or cryogenic cooling).

3. Chemical Reactivity and Built‑Up Edge (BUE) Formation

Titanium becomes chemically reactive with tool materials like carbides at elevated temperatures, leading to adhesion of workpiece material on the cutting edge. Over time, this phenomenon — built‑up edge (BUE) — leads to:

Irregular cutting geometries

Poor surface finishes

Increased cutting forces

Rapid, unpredictable tool wear

Table 3: Chemical Reactivity and Tool Impact

| Factor | Effect on Machining |

|---|---|

| Workpiece–Tool Affinity | Increased BUE |

| Tool Alloy Reaction (Co, TiC) | Diffusion wear |

| Elevated Temp | Chemical bonding |

| Chip Welding | Flank wear & surface damage |

These effects are reported in multiple machining studies on titanium alloys. (PMC)

What this means in practice: titanium does not merely abrade away under cutting; it chemically alters and interacts with the tool material, causing surface welding and diffusion, which degrade the tool substrate and coating.

4. High Cutting Forces and Work Hardening

Titanium’s high strength and work‑hardening propensity make it difficult for a tool to engage smoothly. As the cutting action proceeds, the material around the cutting zone can harden, requiring even greater force for subsequent cuts. (TiRapid)

Table 4: Cutting Force and Work Hardening Effects

| Process | Influence on Tool Life |

|---|---|

| Work Hardening | Increased cutting force |

| Elevated Cutting Force | Higher tool stress |

| Vibration & Chatter | Accelerated wear |

| Surface Work Hardening | Poor surface finish |

Machinists often see a hardened layer form at the cut surface, making it progressively more difficult to maintain smooth cutting without increasing forces and aggravating wear.

5. Elastic Deformation and Machine Rigidity Requirements

Titanium’s low elastic modulus (~110 GPa) relative to steels (~200 GPa) means that it deforms more easily under load. (Makino)

This elasticity leads to:

Springback — after the cut, the material returns toward its original shape, making dimensional control difficult. (华纳工具)

Vibration/chatter — because the workpiece can deflect under cutting forces, the cutting tool experiences unstable engagement, often manifesting as chatter. (Standard Machining)

Table 5: Effects of Elastic Modulus on Machining

| Material | Elastic Modulus (GPa) | Machining Impact |

|---|---|---|

| Ti‑6Al‑4V | ~110 | High springback & vibration |

| 304 Stainless | ~200 | Lower deflection |

| 4140 Steel | ~205 | Better rigidity |

| 6061 Aluminum | ~69 | Low hardness, easier cutting |

For thin‑walled parts or components with flexible features, fixture design and machine rigidity become especially critical.

6. Chip Formation and Evacuation Issues

Titanium chips are often long, continuous, and gummy, which means they:

Trap heat near the tool

Wrap around tooling and fixtures

Lead to accidental contact with the spindle or workpiece

Interrupt coolant delivery

Table 6: Typical Chip Behaviors and Problems

| Chip Type | Cause | Machining Problem |

|---|---|---|

| Long, continuous | Low thermal conductivity | Chip entanglement |

| Gummy chips | High adhesion | Surface damage |

| Serrated chips | Work hardening | Vibration/chatter |

| Sticky chips | Chemical reactivity | BUE formation |

Chip evacuation strategies (e.g., optimized flute geometry, high‑pressure coolant, chip augers) are crucial for stable machining conditions.

7. Tool Wear Mechanisms in Titanium Machining

Titanium exhibits several dominant tool wear mechanisms:

Adhesion Wear — due to titanium sticking to tool surfaces

Abrasion Wear — from hard titanium oxides and particles

Diffusion Wear — chemical migration of tool elements into the workpiece

Crater Wear — localized tool depression due to chemical attack

Scientific studies confirm that adhesion, abrasion, and diffusion are primary wear drivers in titanium machining. (PMC)

8. Cutting Parameters Optimization for Titanium

Compared with materials like aluminum, titanium machining requires significantly different parameters to balance tool life and productivity.

Table 7: Representative Cutting Parameters (Machining Comparisons)

| Material | Cutting Speed (m/min) | Feed (mm/tooth) | Depth of Cut (mm) |

|---|---|---|---|

| Ti‑6Al‑4V | 30–60 | 0.10–0.20 | 0.5–2.5 |

| 6061 Aluminum | 300–600 | 0.30–0.60 | 1.0–5.0 |

| 304 Stainless | 40–90 | 0.20–0.50 | 1.0–3.5 |

Compared machining parameter ranges illustrate how titanium requires much lower cutting speeds and careful control of feeds. (优控科技)

Lower speeds reduce heat generation but extend cycle times; higher feeds can improve chip breaking but raise forces.

9. Tooling Selection for Titanium Machining

Effective tooling strategies include:

Coated carbide (TiAlN, AlTiN) — improved oxidation resistance

CBN or ceramic tools (in special cases) — for high temperatures

Positive rake geometries — reduce cutting forces

Sharp edge tools — reduce rubbing and heat generation

Advanced process planning — including toolpath optimization and dynamic milling — helps reduce dwell times and tool stress. Guides and tooling strategies are further documented in machining knowledge bases such as https://www.eadetech.com.

10. Coolant & Thermal Control Strategies

Effective cooling is critical due to localized heat at the cutting interface:

High‑pressure flood coolant — to break chips and cool tools

Cryogenic cooling (LN₂) — helps manage extreme heat

Mist and air coolant — where flood is not feasible

Without proper cooling, localized temperatures can exceed 800–1000 °C, accelerating tool degradation. (Hopeful)

11. Workholding and Fixture Design Impacts

Because of springback and elasticity, robust fixturing is essential. Poor workholding increases:

Tool chatter and vibration

Dimensional deviation

Tool failure due to unexpected displacement

Designing fixtures that minimize part movement and absorb cutting forces greatly improves machining outcomes.

12. Surface Integrity and Quality Issues

Titanium machining problems extend beyond tool wear:

Surface roughness degradation due to tool edge wear

Subsurface work hardening from repeated cutting

Residual stresses that can warp parts

Monitoring surface integrity with proper inspection ensures that functional performance is maintained.

13. Economics of Titanium Machining

Because of slower speeds, high tool wear, and complex thermal management, titanium machining is more costly:

Higher tooling cost

Longer cycle times

Frequent tool changes

More advanced setup and coolant systems

Despite costs, titanium’s high strength‑to‑weight and corrosion resistance justify its use in critical applications.

14. Emerging Solutions and Process Enhancements

Modern strategies to mitigate machining difficulties include:

Adaptive machining and CAM toolpath optimization

In‑situ temperature monitoring

Vibration‑damping fixtures

Hybrid additive–subtractive processes

These approaches aim to optimize tool life and part quality simultaneously.

15. Conclusion

Titanium’s unique and valuable material properties — low thermal conductivity, high strength, chemical reactivity, work hardening, and elasticity — all make it extremely difficult to machine. Unlike chopping through aluminum or mild steel, machining titanium demands a deep understanding of metallurgy, thermodynamics, tooling, and process control.

Successful titanium machining requires:

✔ Optimized cutting parameters

✔ Specialized tool materials and coatings

✔ Effective cooling and chip evacuation

✔ Rigid machine and fixture setup

✔ Continuous tool monitoring

Each of these elements plays a role in navigating the challenges posed by titanium. For more insights into precision machining strategies and tooling choices for difficult‑to‑cut alloys like titanium, resources such as https://www.eadetech.com provide practical examples and technical guidance.

CATEGORIES

LATEST NEWS

CONTACT US

Whatsapp: +8618998453346

Phone: +8618998453346

Tel: +8618998453346

Email: [email protected]

Addr: Room 302, Building D, COFCO Gonghua Project, Zone 20, Honglang Community, Xin'an Street, Bao'an District, Shenzhen City.