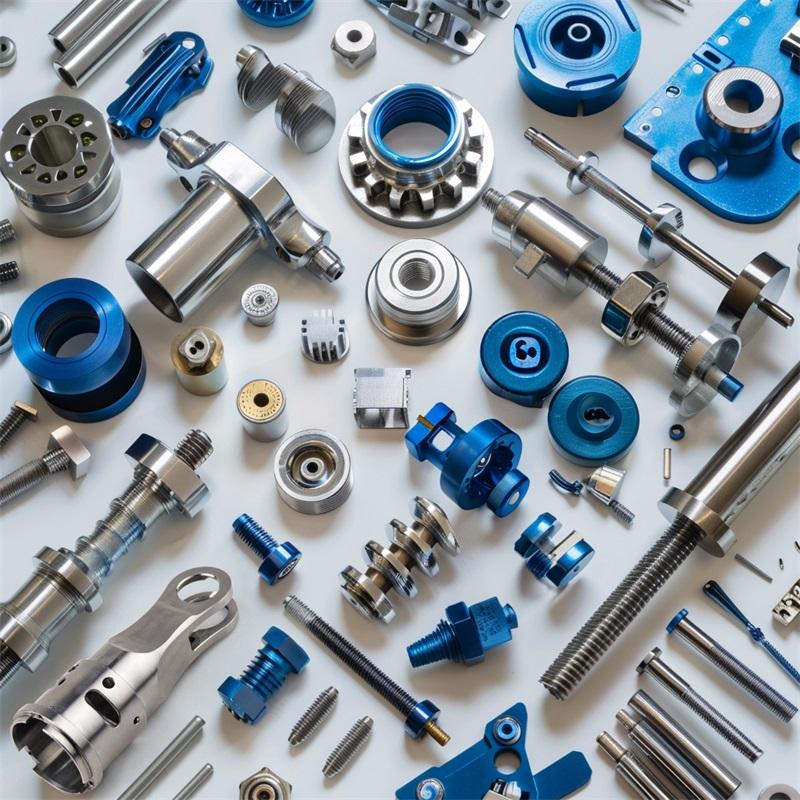

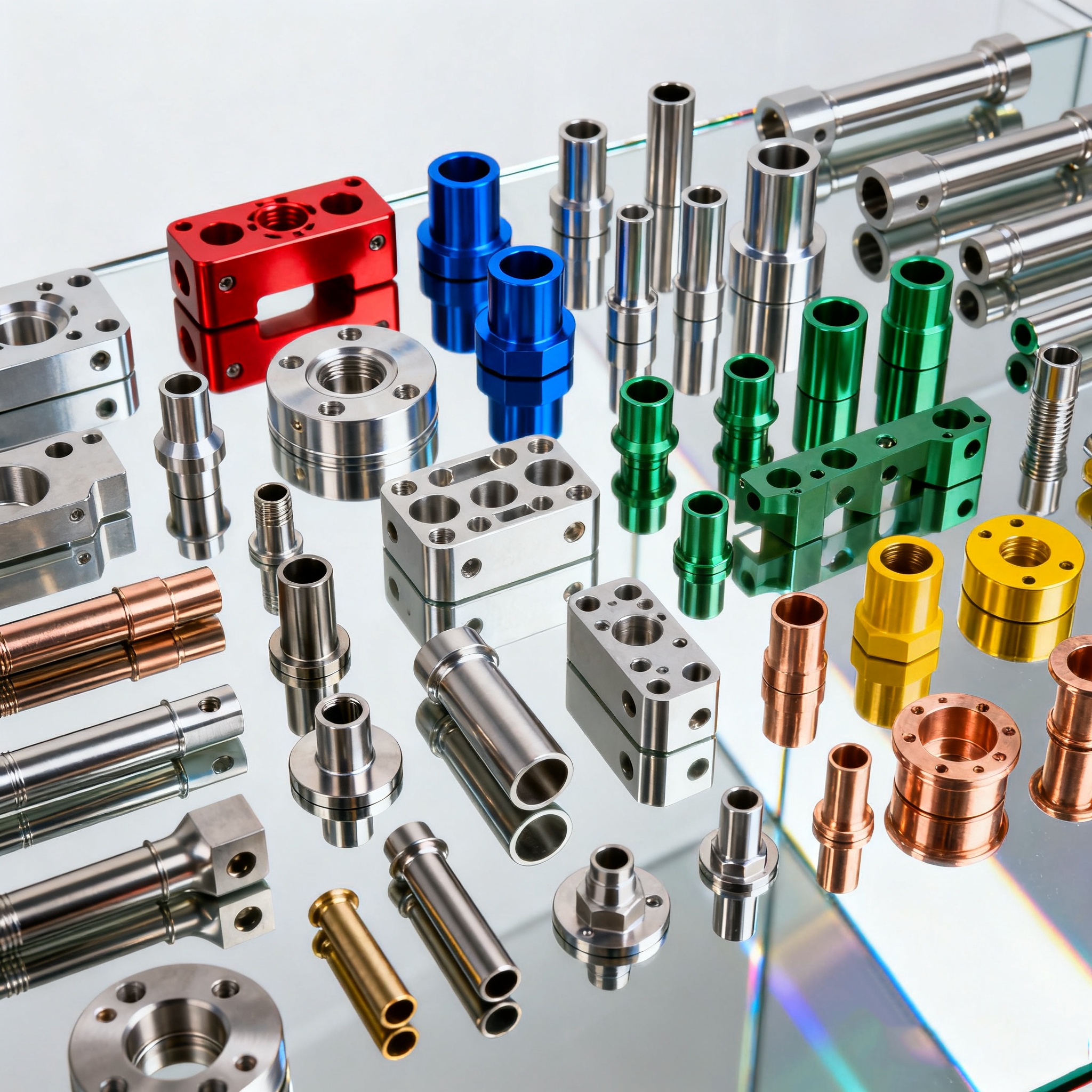

Titanium CNC Turning Parts

Titanium Turning and CNC Lathe Machining for Precision Shafts and Sleeves

- Product ID: Titanium CNC Turning Parts

- Tel: +8618998453346

- WhatsApp: +8618998453346

- Tel: +8618998453346

- Email: [email protected]

- Time: 2024-08-18 18:25

- Price: 0

Heat concentration at the cutting edge

Tool wear during continuous turning

Maintaining dimensional stability on long, slender parts

Rough turning for diameter reduction

Finish turning for precision outer diameters

Internal boring for sleeves and bushings

Milling keyways or flats

Drilling cross-holes

Final edge finishing

CMM inspection for concentricity and straightness

Gauge measurement for diameters and bores

100% visual inspection

Optimizing lathe tooling and cutting parameters

Minimizing vibration during turning

Supporting prototype and batch production

Aerospace actuator shafts

Medical device sleeves

Precision robotic components

Background: Precision Shaft and Sleeve Requirements

Background: Precision Shaft and Sleeve Requirements

Precision titanium shafts and sleeves are widely used in aerospace, medical equipment, robotics, and energy systems. These components require excellent concentricity, smooth surface finish, and consistent dimensional accuracy.

In this case, the customer required titanium shafts with tight diameter tolerances and sleeves with precise internal bores. Titanium turning using CNC lathes was selected to meet these requirements efficiently.

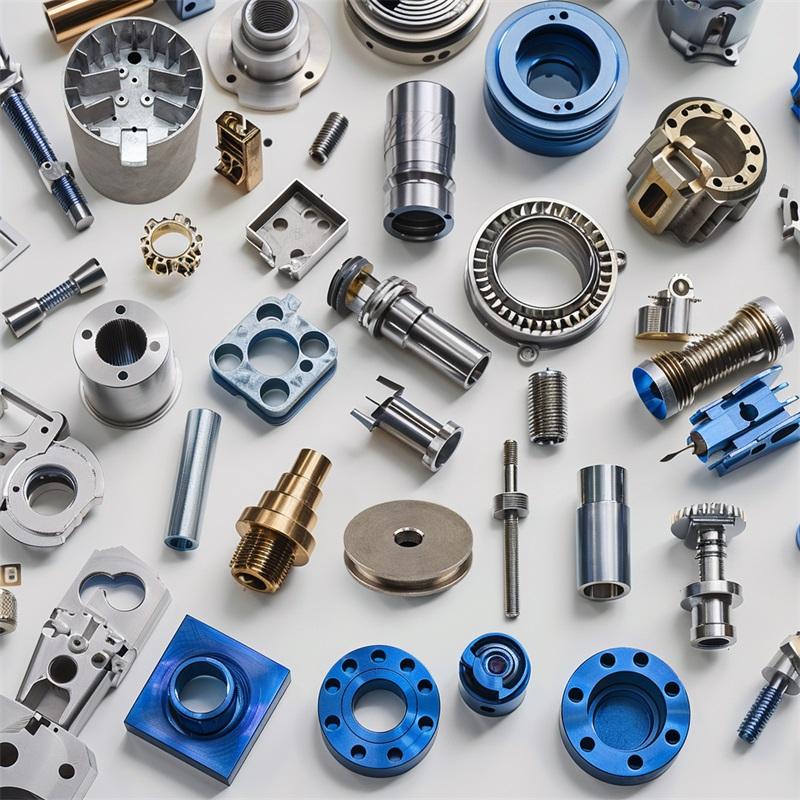

Material Selection and Titanium Machinability

Titanium alloys were selected for their high strength, corrosion resistance, and lightweight properties. However, titanium machinability presents challenges such as:

Understanding the machinability of titanium alloys was essential to achieve stable turning performance.

Titanium Turning and CNC Lathe Process

Titanium lathe turning operations included:

CNC lathe programming ensured consistent cutting conditions and repeatable results.

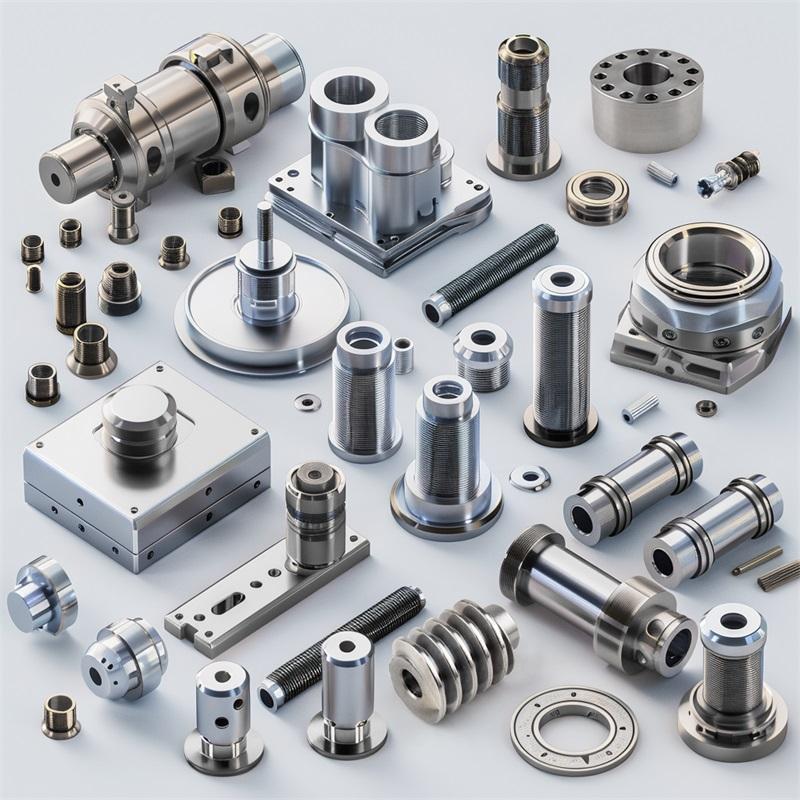

Precision Control and Surface Finish

All shaft diameters and bore dimensions were controlled within ±0.01 mm tolerance. Surface finishes were optimized to reduce friction and improve assembly performance. Precision titanium machining ensured concentricity and straightness along the full length of the components.

Integration with CNC Machining Operations

After turning, selected parts underwent CNC machining for:

This combination produced fully functional machined titanium parts ready for assembly.

Inspection and Quality Assurance

Quality control included:

These steps ensured all CNC titanium parts met customer specifications.

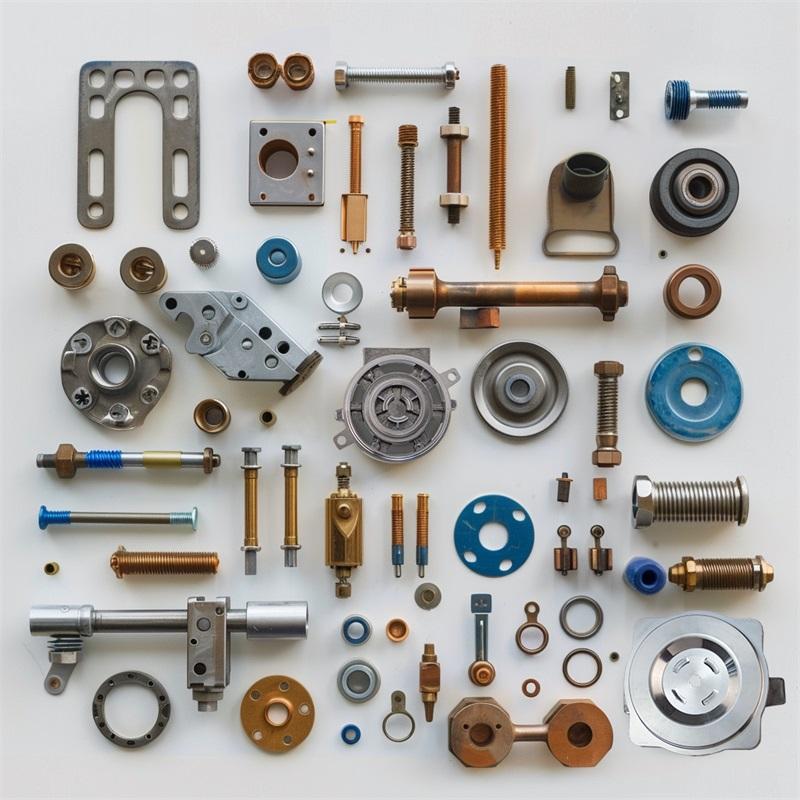

OEM and Engineering Support

Engineering teams supported the project by:

CAD and CAM tools were used for programming, with support for STEP, DWG, DXF, IGS, STL, and PDF formats.

Applications of Titanium Shafts and Sleeves

Titanium turning is commonly used for:

Titanium provides durability, corrosion resistance, and long-term dimensional stability.

Conclusion

This case shows how titanium turning combined with CNC lathe machining delivers high-precision shafts and sleeves. By addressing titanium machinability challenges and implementing strict inspection standards, reliable and accurate machined titanium parts were produced for demanding applications.

CATEGORIES

LATEST NEWS

CONTACT US

Whatsapp: +8618998453346

Phone: +8618998453346

Tel: +8618998453346

Email: [email protected]

Addr: Room 302, Building D, COFCO Gonghua Project, Zone 20, Honglang Community, Xin'an Street, Bao'an District, Shenzhen City.