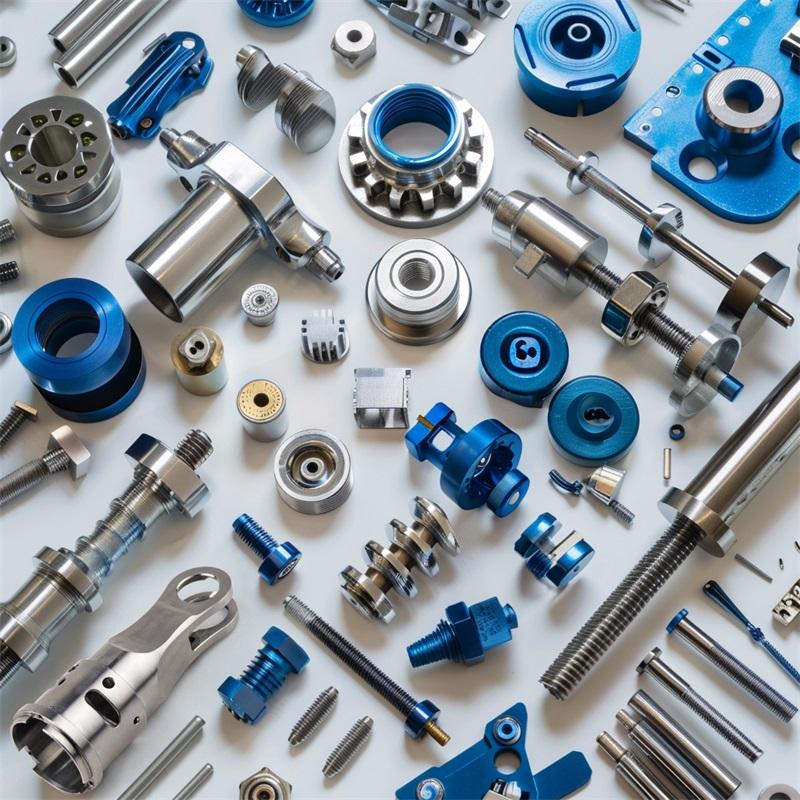

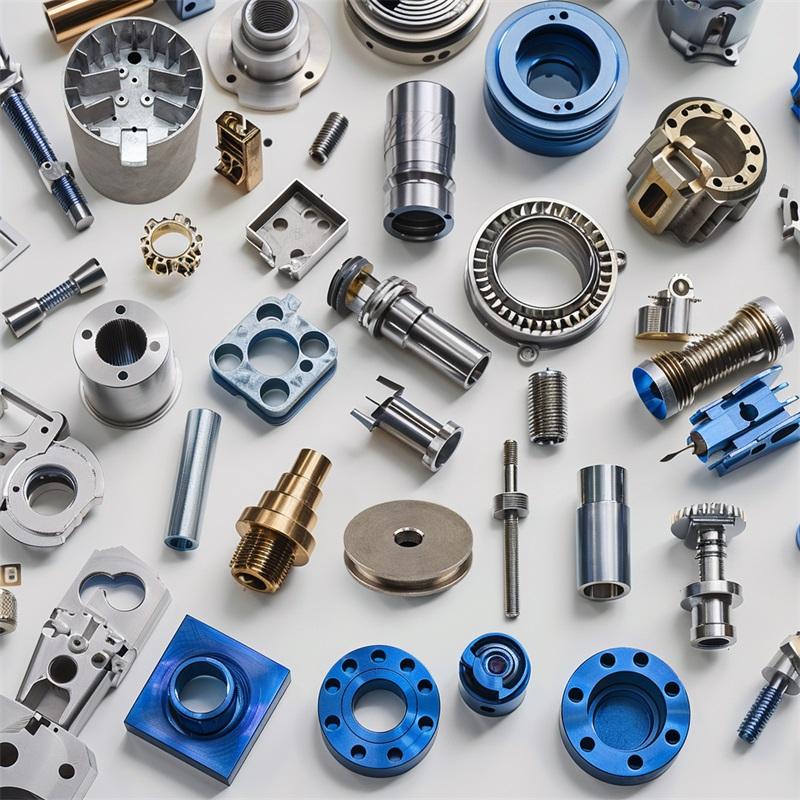

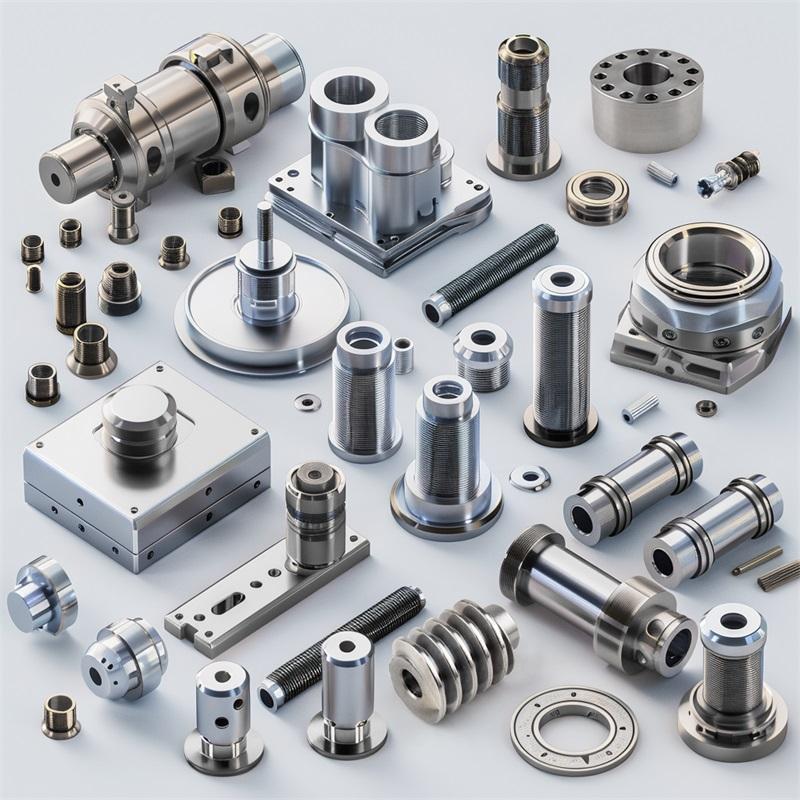

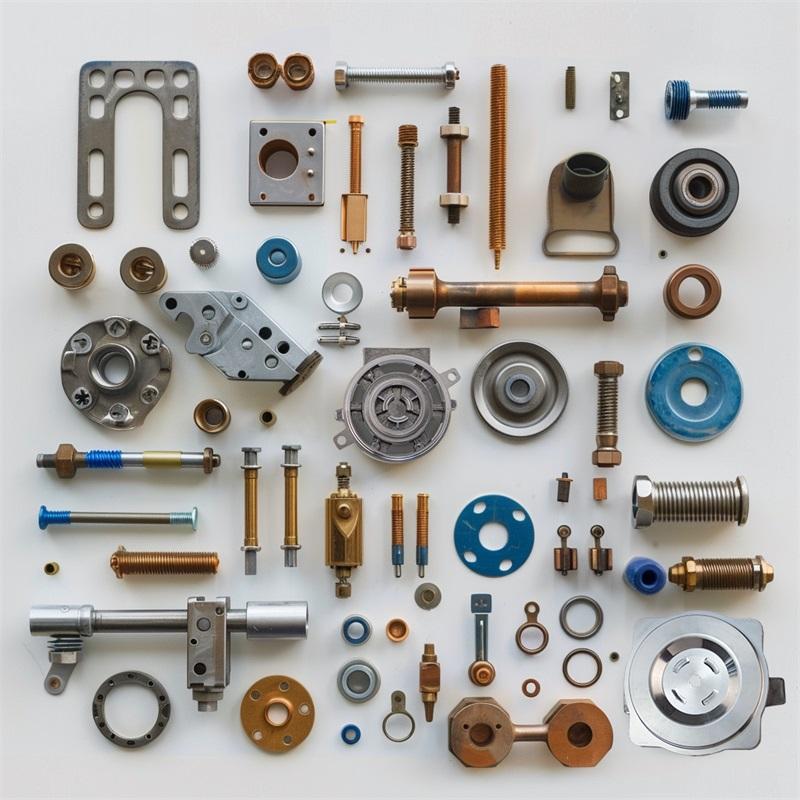

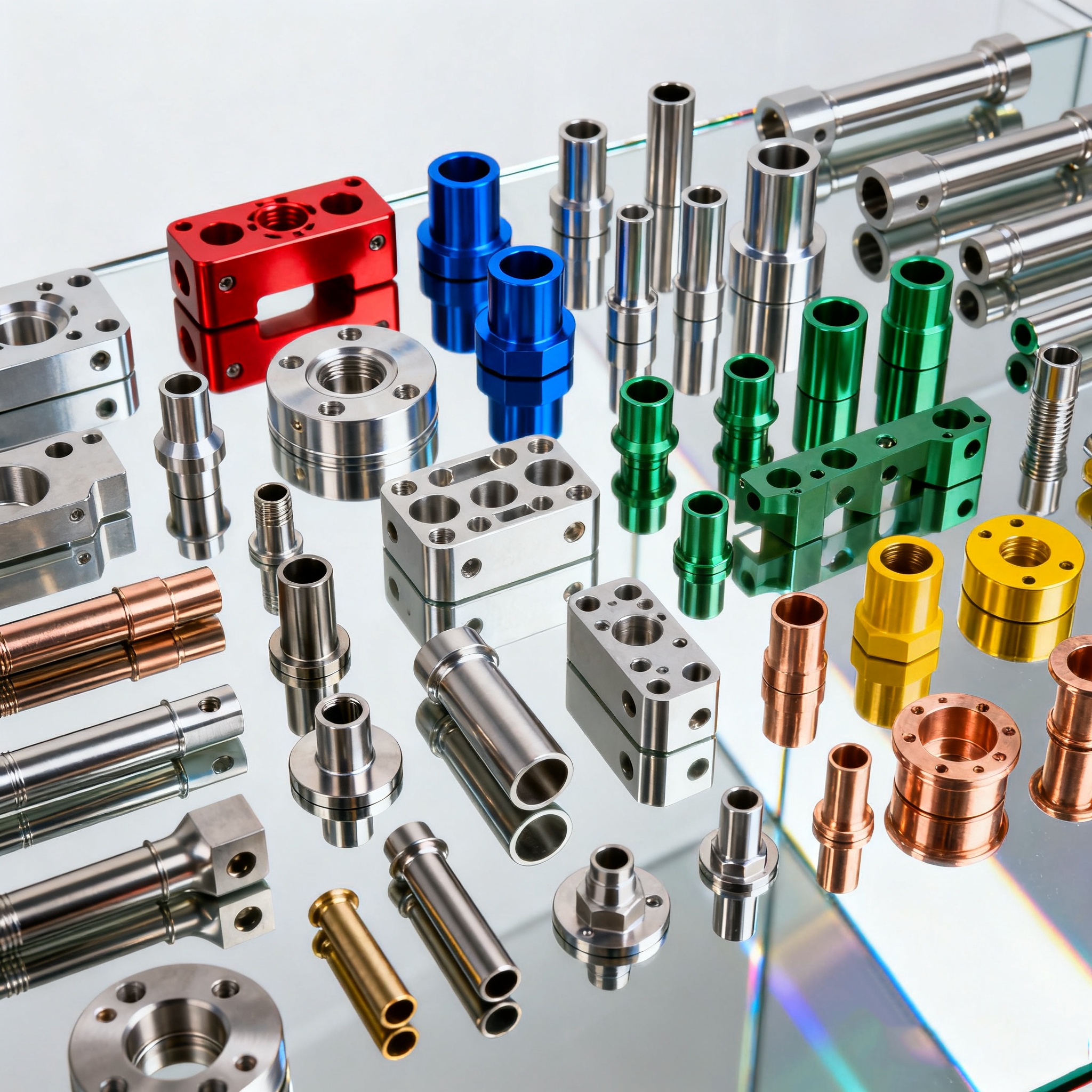

Titanium CNC Turning Parts

Titanium Waterjet Cutting and CNC Machining for Large Flat Components

- Product ID: Titanium CNC Turning Parts

- Tel: +8618998453346

- WhatsApp: +8618998453346

- Tel: +8618998453346

- Email: [email protected]

- Time: 2024-08-18 18:22

- Price: 0

Avoiding heat-affected zones during cutting

Maintaining flatness on large surfaces

Ensuring edge quality for subsequent machining

Programming complex profiles and internal cutouts

High-pressure abrasive jet cutting for clean edges

Maintaining consistent kerf width across large sheets

Face milling for flat reference surfaces

Drilling and tapping assembly holes

Milling slots and pockets with tight tolerances

CMM inspection of profiles and hole positions

100% visual inspection of cut edges

Gauge verification for thickness and flatness

Optimize waterjet cutting layouts for material efficiency

Plan CNC machining sequences for large components

Validate prototypes before production

Aerospace structural panels

Energy equipment mounting plates

Industrial machine frames

Background: Large Flat Titanium Component Requirements

Background: Large Flat Titanium Component Requirements

Large flat titanium components are widely used in aerospace structures, energy equipment, and industrial machinery. These parts often require accurate profiles, minimal distortion, and high flatness across large surface areas.

In this case, the customer required large titanium plates with complex outer profiles and multiple internal cutouts. Titanium waterjet cutting was selected for rough shaping, followed by CNC machining for precision features.

Material Selection and Titanium Machinability

Titanium alloys were chosen for their corrosion resistance, strength, and structural stability. Machinability considerations included:

Waterjet titanium cutting provided cold cutting without thermal distortion, preserving material properties.

Titanium Waterjet Cutting Process

Waterjet cutting operations included:

Titanium waterjet cutting produced accurate near-net-shape blanks suitable for CNC machining.

CNC Titanium Machining for Precision Features

After waterjet cutting, CNC machining was applied to:

Precision titanium machining ensured all functional features met design requirements.

Dimensional Accuracy and Flatness Control

Flatness and dimensional tolerances were controlled within ±0.01 mm on critical features. Large surface areas were inspected using CMM and straightness gauges to ensure consistent geometry.

Inspection and Quality Assurance

Quality control methods included:

These steps ensured all machined titanium parts met specification.

OEM and Engineering Collaboration

Engineering teams collaborated with the customer to:

CAD, CAM, and CAE tools were used, with drawing formats including STEP, DWG, DXF, IGS, STL, and PDF.

Applications of Large Flat Titanium Parts

Titanium waterjet cutting combined with CNC machining is widely used for:

This process ensures minimal distortion and high precision for large titanium components.

Conclusion

This case demonstrates how titanium waterjet cutting combined with CNC machining produces large flat components with excellent dimensional accuracy and minimal distortion. Cold cutting, precise machining, and thorough inspection ensure reliable, high-quality machined titanium parts for demanding applications.

CATEGORIES

LATEST NEWS

CONTACT US

Whatsapp: +8618998453346

Phone: +8618998453346

Tel: +8618998453346

Email: [email protected]

Addr: Room 302, Building D, COFCO Gonghua Project, Zone 20, Honglang Community, Xin'an Street, Bao'an District, Shenzhen City.