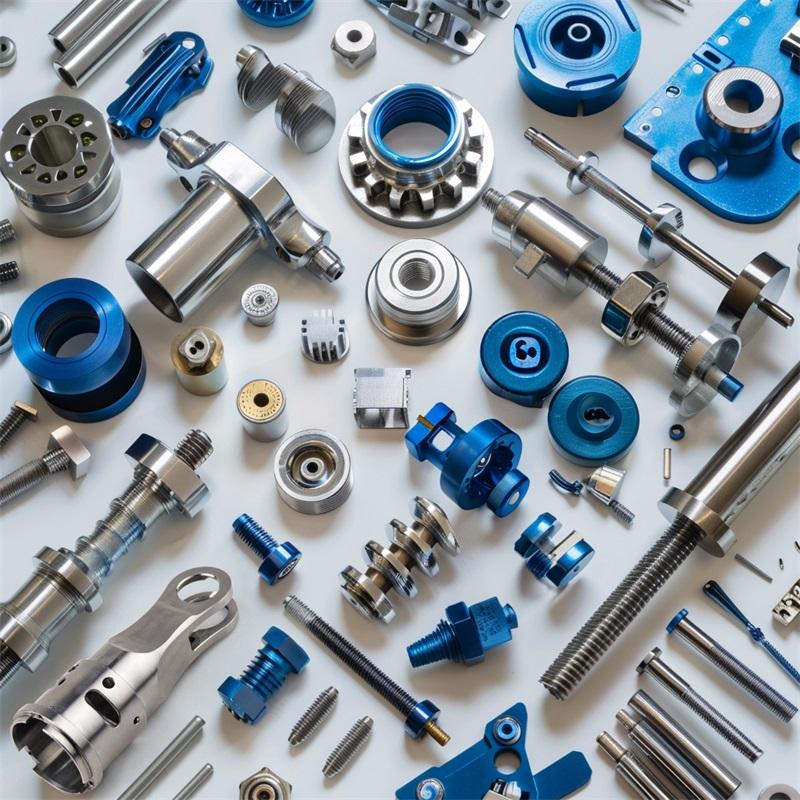

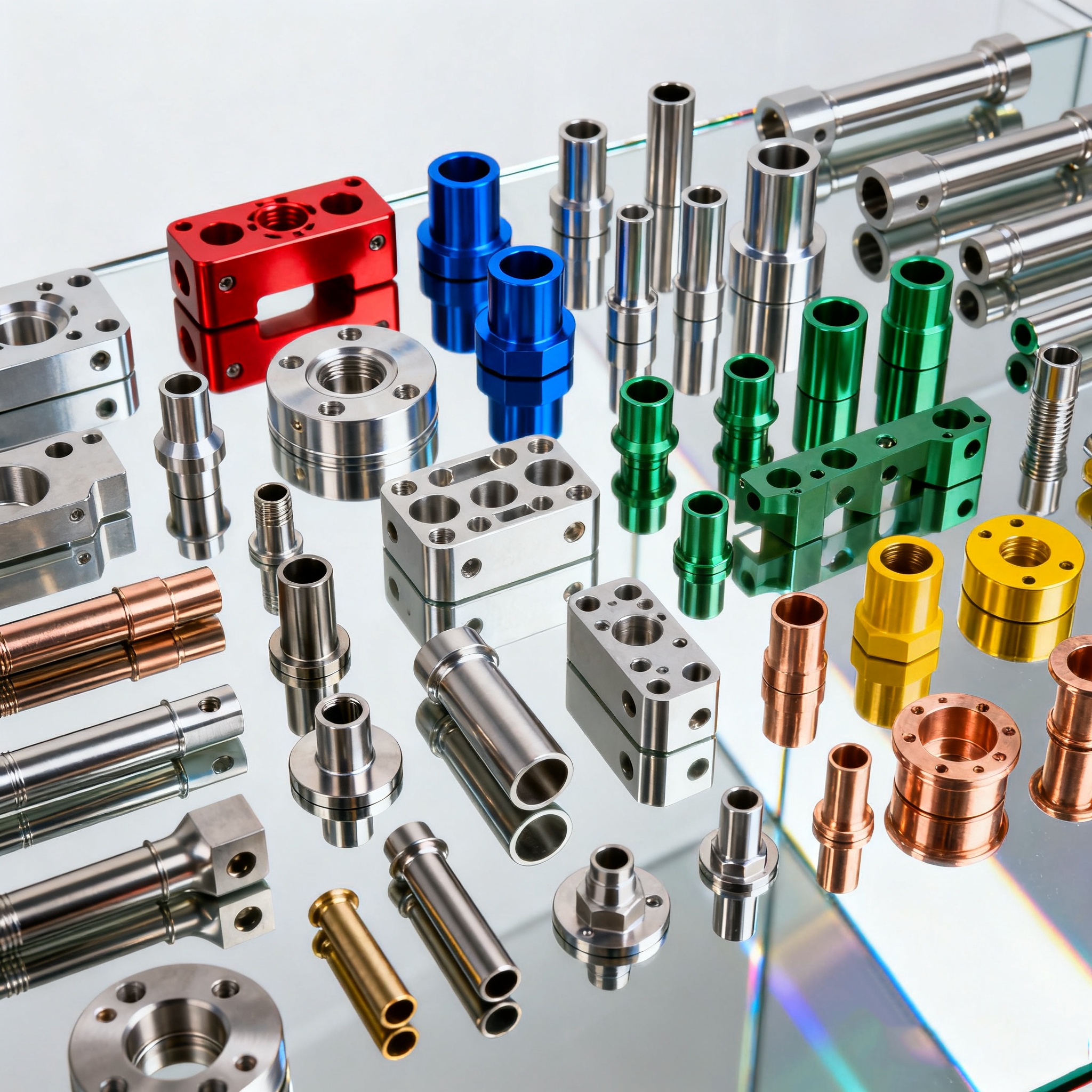

Titanium CNC Turning Parts

Titanium Machining for Automotive and Motorcycle Performance Components

- Product ID: Titanium CNC Turning Parts

- Tel: +8618998453346

- WhatsApp: +8618998453346

- Tel: +8618998453346

- Email: [email protected]

- Time: 2024-08-18 18:09

- Price: 0

Heat buildup during aggressive cutting

Tool wear during extended machining cycles

Maintaining accuracy on thin and complex geometries

Milling complex geometries for lightweight structures

Drilling and tapping for assembly interfaces

Precision contouring for performance-critical surfaces

CMM inspection for dimensional verification

Gauge measurement of critical features

100% visual inspection

Optimize designs for machinability and weight reduction

Improve production efficiency

Support prototype development and small-batch performance builds

Performance brackets and mounts

Structural connectors and supports

Lightweight components for racing and high-performance vehicles

Background: Automotive and Motorcycle Performance Requirements

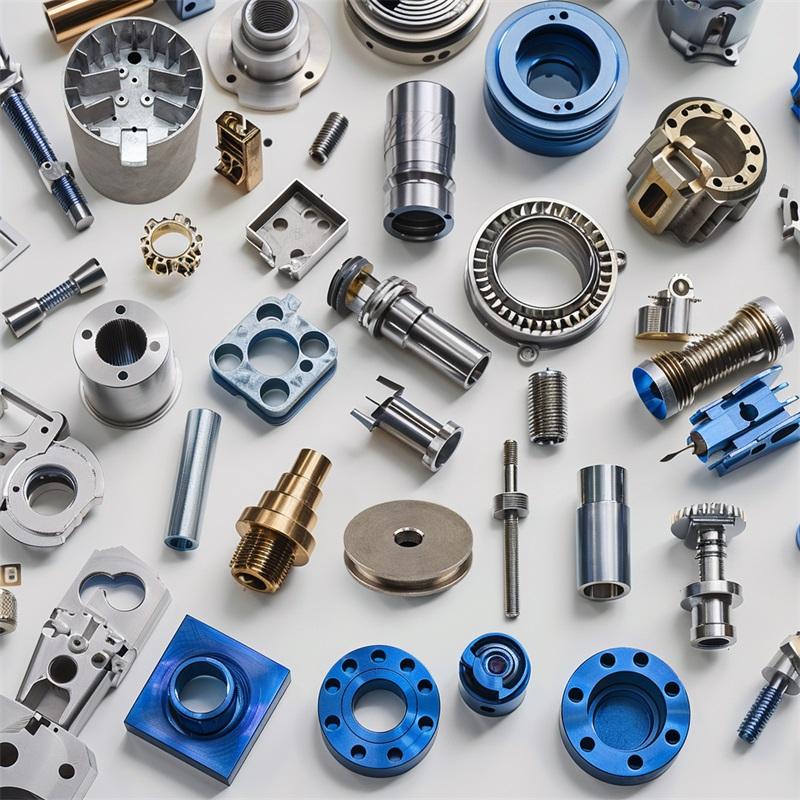

High-performance automotive and motorcycle components demand lightweight construction, high strength, and resistance to heat and corrosion. Titanium is increasingly used in performance applications to reduce weight while maintaining structural integrity.

In this case, the customer required custom titanium components for automotive and motorcycle systems, including brackets, connectors, and performance-related structural parts. CNC titanium machining was selected to meet precision and durability requirements.

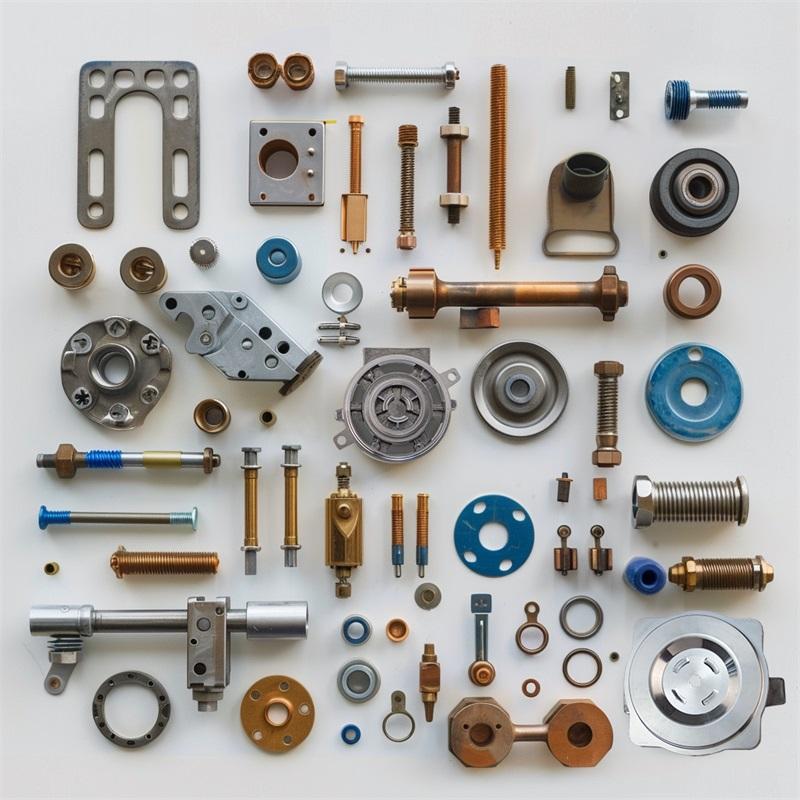

Material Selection and Titanium Machinability

Titanium alloys were selected for their excellent strength-to-weight ratio and thermal stability. However, titanium machinability challenges included:

Understanding the machinability of titanium alloys was essential for producing consistent performance parts.

CNC Titanium Machining Process

CNC machining operations included:

High speed machining titanium strategies were applied to improve efficiency while maintaining accuracy.

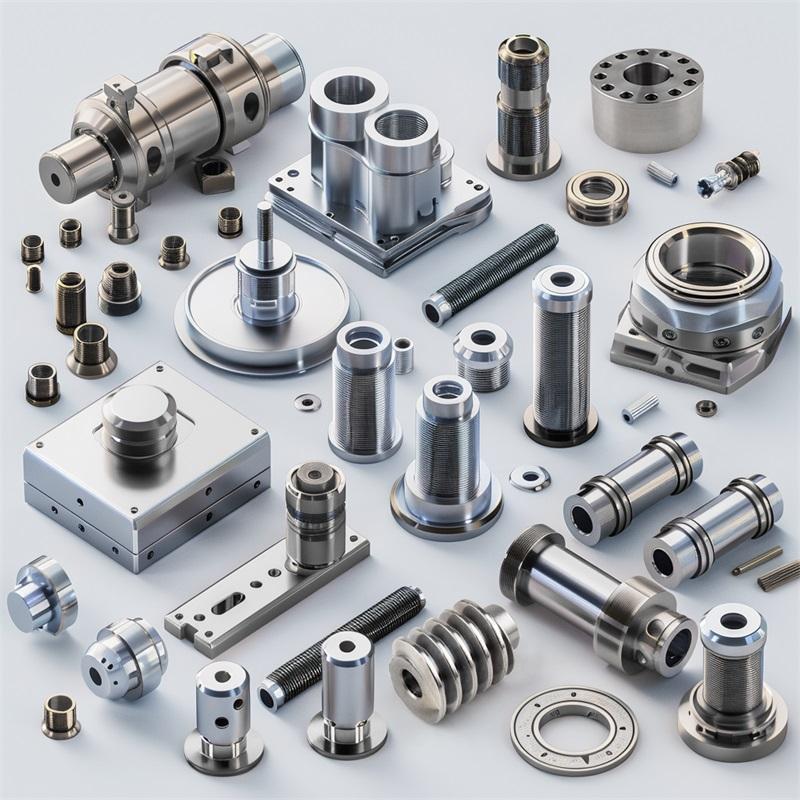

Dimensional Accuracy and Surface Finish

All critical dimensions were maintained within ±0.01 mm tolerance. Surface finishes were optimized to reduce stress concentration and improve durability under dynamic loads. Precision titanium machining ensured repeatability across production batches.

Integration with Assembly Requirements

Machined titanium parts were designed to integrate seamlessly with existing automotive and motorcycle assemblies. Tight tolerances ensured proper alignment and secure fastening in high-vibration environments.

Inspection and Quality Control

Quality assurance processes included:

These inspections ensured all CNC titanium parts met performance and safety requirements.

OEM and Engineering Collaboration

Engineering teams collaborated closely with automotive and motorcycle manufacturers to:

CAD, CAM, and CAE tools were used, supporting STEP, DWG, DXF, IGS, STL, and PDF formats.

Applications in Automotive and Motorcycle Industry

Titanium machining is widely used for:

Titanium CNC parts provide strength, durability, and reduced weight.

Conclusion

This case demonstrates how CNC titanium machining delivers high-quality automotive and motorcycle performance components. By addressing titanium machinability challenges and applying high speed machining strategies, precise and durable machined titanium parts were produced for demanding performance applications.

CATEGORIES

LATEST NEWS

CONTACT US

Whatsapp: +8618998453346

Phone: +8618998453346

Tel: +8618998453346

Email: [email protected]

Addr: Room 302, Building D, COFCO Gonghua Project, Zone 20, Honglang Community, Xin'an Street, Bao'an District, Shenzhen City.