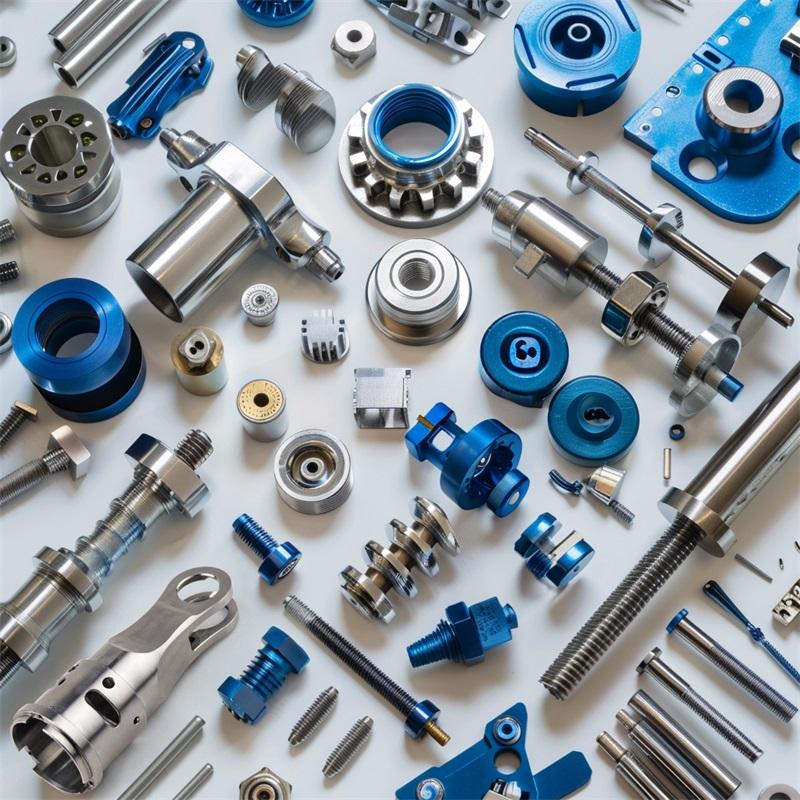

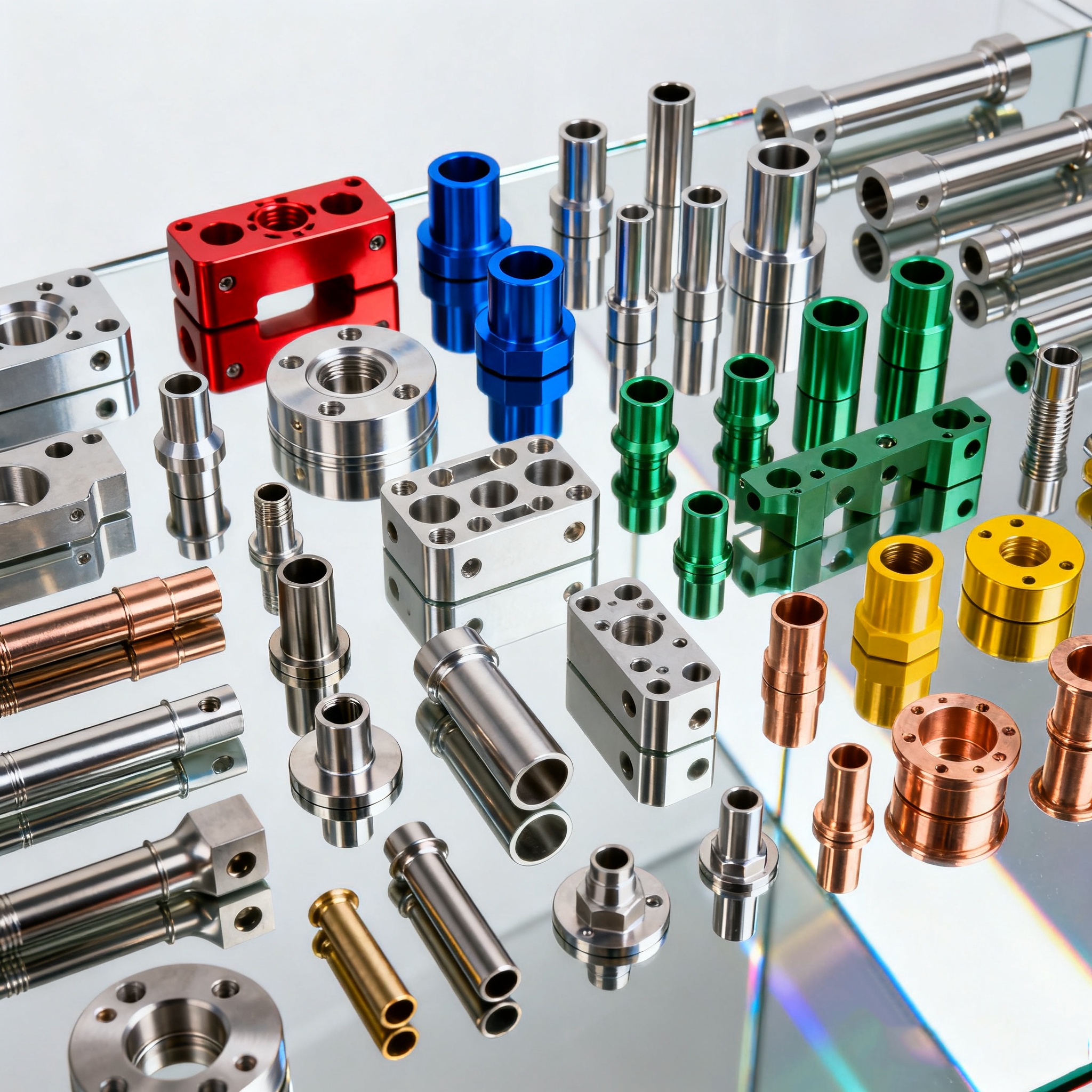

Titanium CNC Turning Parts

Titanium Broaching and CNC Machining for Internal Profiles and Keyways

- Product ID: Titanium CNC Turning Parts

- Tel: +8618998453346

- WhatsApp: +8618998453346

- Tel: +8618998453346

- Email: [email protected]

- Time: 2024-08-18 18:06

- Price: 0

Work hardening during cutting

Maintaining tolerance on internal profiles

Avoiding distortion in thin-walled or delicate components

Internal profile broaching for keyways

Controlled feed rates to minimize work hardening

Precision alignment to maintain concentricity

Finish external diameters and surfaces

Drill mounting holes or tapped threads

Ensure overall dimensional accuracy

CMM inspection for internal profiles and keyway positions

Gauge measurement for critical diameters

100% visual inspection

Optimize broaching and machining sequences

Ensure correct tool selection and cutting parameters

Validate prototypes before batch production

Automotive transmission components

Aerospace coupling and shaft assemblies

Industrial machine parts requiring precision keyways

Background: Internal Profiles and Keyway Requirements

Internal profiles and keyways are critical features in many industrial, automotive, and aerospace components. Titanium’s strength and corrosion resistance make it an ideal material for high-performance keyways, shafts, and mating components.

In this case, the customer required titanium parts with precise internal profiles and keyways, demanding tight tolerances and smooth finishes. Titanium broaching combined with CNC machining was selected to achieve these requirements.

Material Selection and Titanium Machinability

Titanium alloys were chosen for their durability, corrosion resistance, and machinability characteristics. Machinability challenges included:

Understanding the machinability of titanium alloys ensured successful broaching and machining operations.

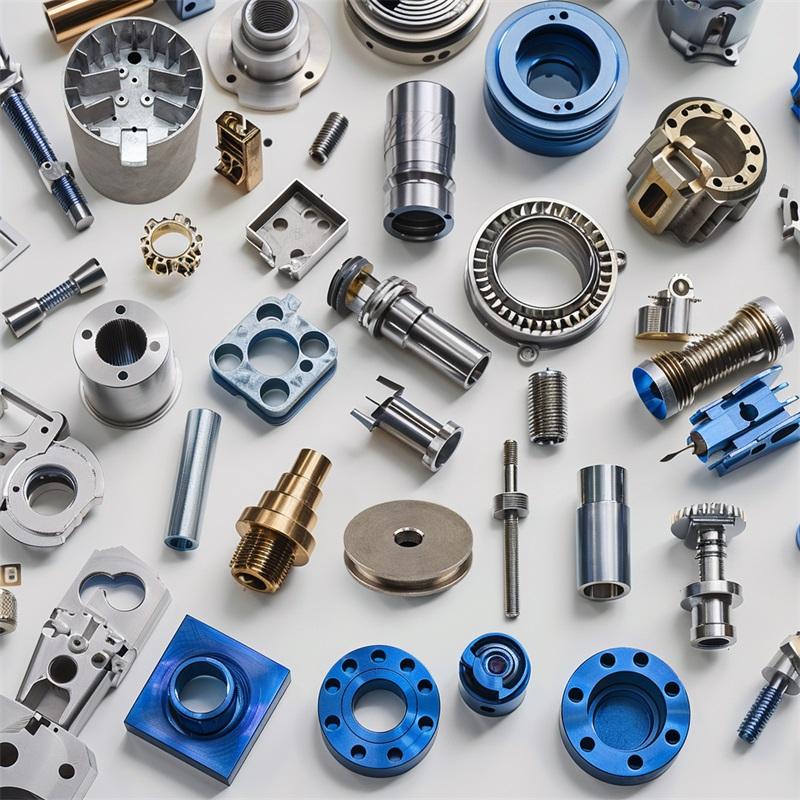

Titanium Broaching Process

Titanium broaching operations included:

Broaching titanium ensured accurate, repeatable internal features suitable for assembly.

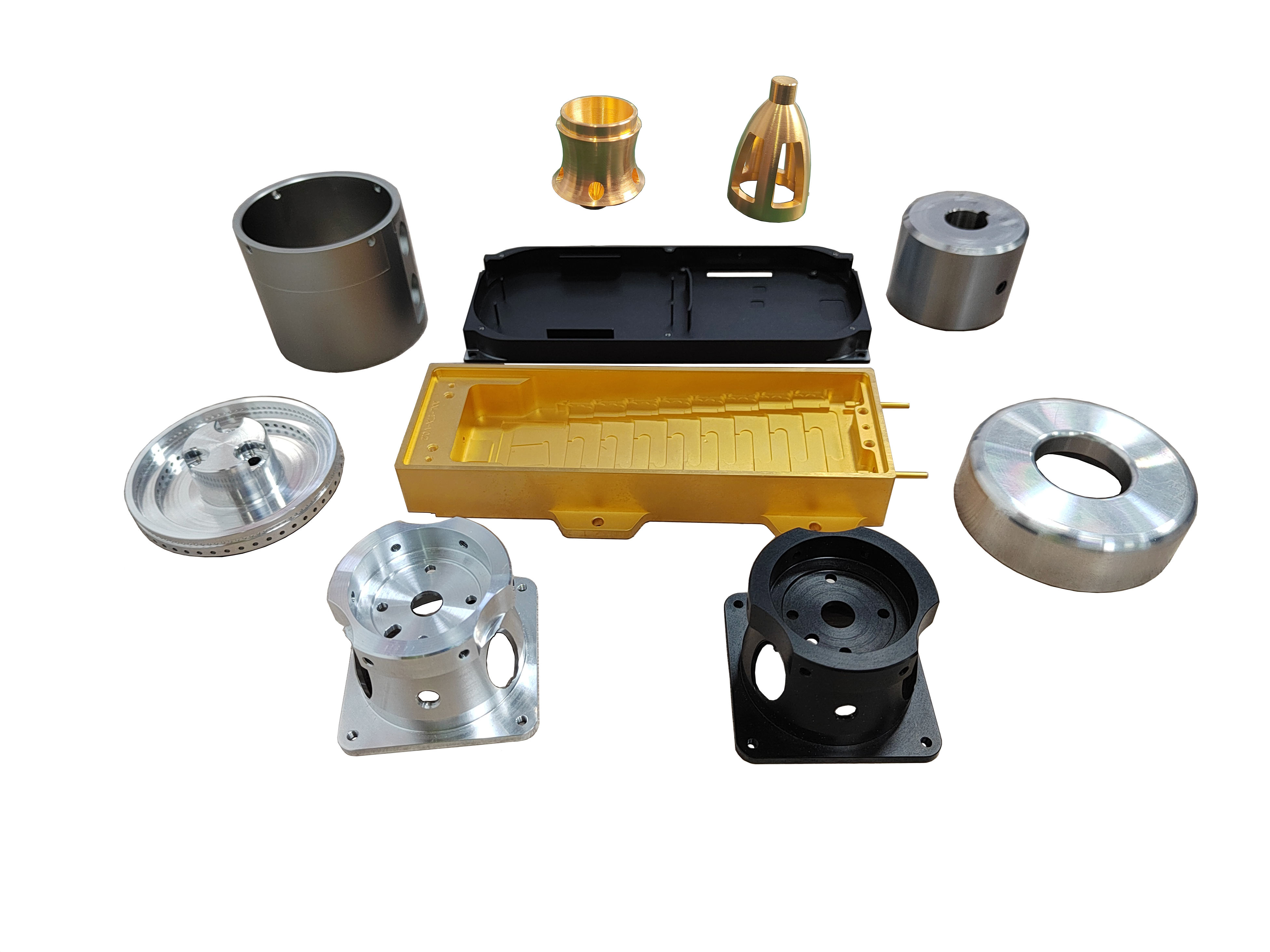

CNC Titanium Machining Integration

After broaching, CNC machining operations were performed to:

Precision titanium machining ensured the final parts met design specifications.

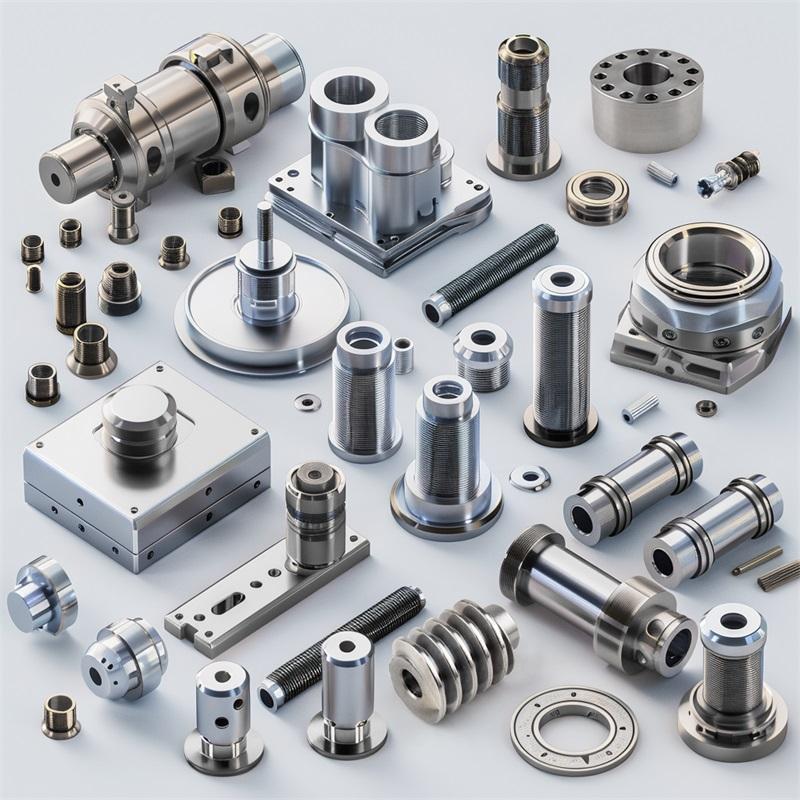

Dimensional Accuracy and Surface Quality

All critical dimensions, including internal keyways and external surfaces, were held within ±0.01 mm. Surface finishes were optimized for smooth assembly and long-term wear resistance.

Inspection and Quality Assurance

Inspection methods included:

These steps ensured all machined titanium parts met exacting standards.

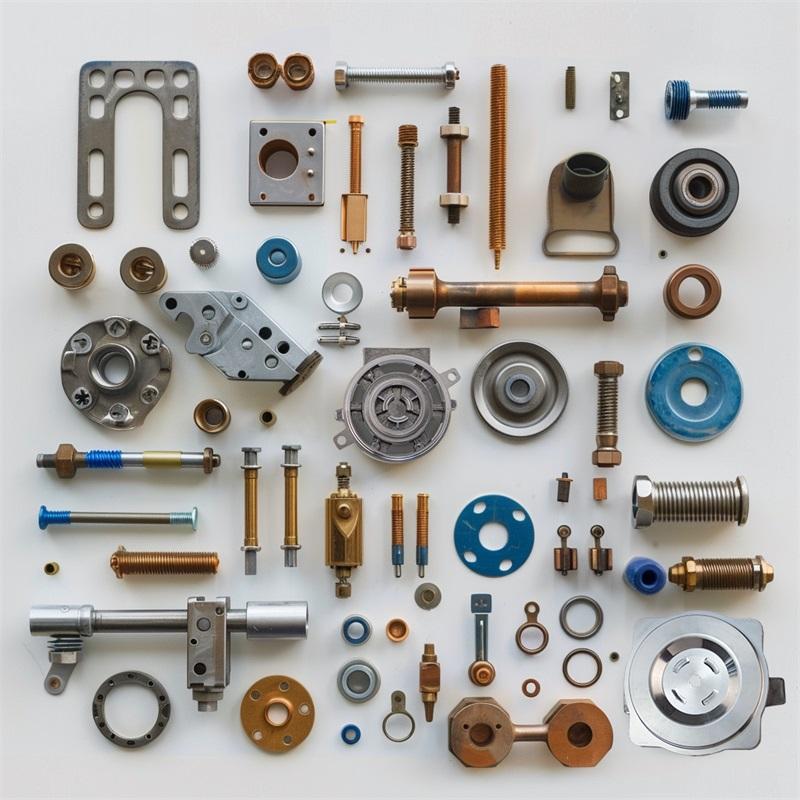

OEM and Engineering Collaboration

Engineering teams collaborated to:

CAD, CAM, and CAE tools supported STEP, DWG, DXF, IGS, STL, and PDF formats.

Applications of Broached Titanium Components

Titanium broaching combined with CNC machining is widely used for:

These processes ensure strong, accurate, and durable titanium components.

Conclusion

This case demonstrates how titanium broaching and CNC machining produce precise internal profiles and keyways. By addressing titanium machinability challenges and implementing strict inspection protocols, reliable and high-quality machined titanium parts were delivered for demanding industrial applications.

CATEGORIES

LATEST NEWS

CONTACT US

Whatsapp: +8618998453346

Phone: +8618998453346

Tel: +8618998453346

Email: [email protected]

Addr: Room 302, Building D, COFCO Gonghua Project, Zone 20, Honglang Community, Xin'an Street, Bao'an District, Shenzhen City.