Tantalum CNC Turning Parts

Custom CNC Titanium Machining Parts – Advanced 5 Axis Machining Solutions from China

- Product ID: Tantalum CNC Turning Parts

- Tel: +8618998453346

- WhatsApp: +8618998453346

- Tel: +8618998453346

- Email: [email protected]

- Time: 2025-06-23 19:46

- Price: 0

CNC Machining: Supported

5 Axis CNC Machining: Available

Micro Machining: Yes

Custom Manufacturing: Fully supported

CNC Milling

CNC Turning

Drilling & Tapping

Broaching

Wire EDM

Laser Machining

Chemical / Etching Machining

Rapid Prototyping

Hybrid and Custom Machining Solutions

Titanium (custom grades per requirement)

Aluminum

Stainless Steel

Carbon Steel & Steel Alloys

Brass

Bronze

Copper

Hardened Metals

Precious Metals

Metal processing machinery parts

Precision mechanical equipment

Aerospace structural components

Medical and healthcare device housings

Automation and robotics systems

Automotive lightweight applications

Energy, marine, and chemical industries

Mechanical polishing

Sandblasting

Passivation

Anodizing (where applicable)

Special finishes based on customer specifications

Stable tolerance control

Consistent surface finish

Controlled burr removal

Dimensional repeatability across batches

Individual parts protected with polybag packaging

Outer packaging using reinforced cartons

Custom packaging solutions available if required

Selling Unit: Single item

Package Size: 33 × 10 × 5 cm

Gross Weight: 1.000 kg

DHL

UPS

FedEx

Custom drawing-based manufacturing

Prototype development

Small-batch trial production

Medium and large-scale production

Private labeling and trademark support

Specialized experience in titanium machining

Advanced CNC and 5 axis equipment

Flexible customization and fast response

Stable production quality

Export-oriented manufacturing experience

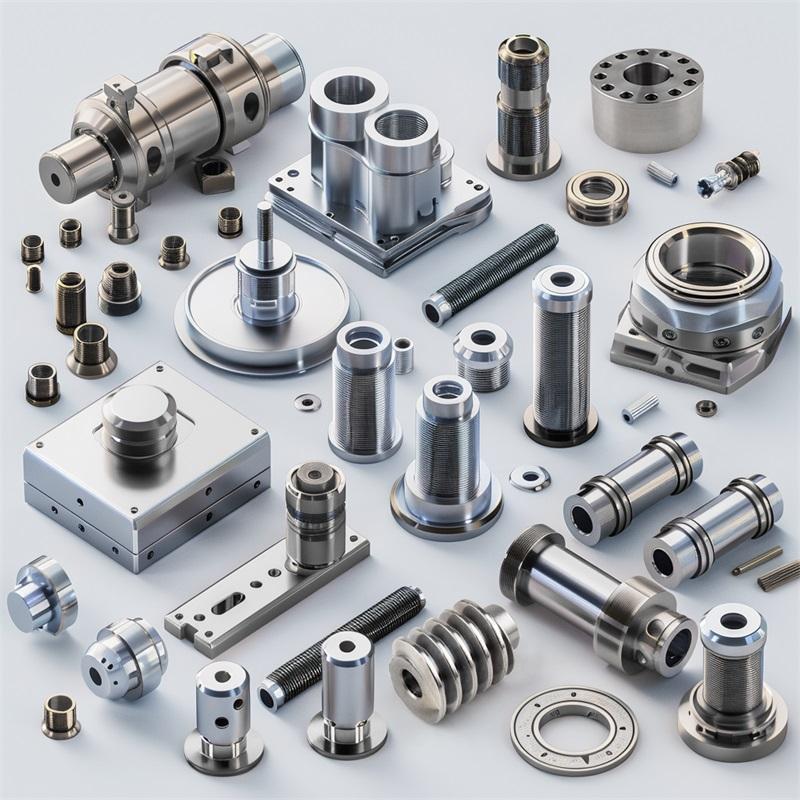

Product Name: Professional Precision CNC Machining Parts

Core Technology: Titanium Machining

Machining Type: CNC Machining, 5 Axis CNC

Micro Machining: Supported

Material: Customer’s Requirement

Process: CNC Machining + Deburring

Surface Treatment: As Requested

Service: OEM / ODM

Place of Origin: China

Application: Metal Processing Machinery Parts

Shipping: DHL / UPS / FedEx/Ship

Introduction to Titanium Machining

Titanium machining is a highly specialized manufacturing process used to produce precision metal components that demand exceptional strength, corrosion resistance, and lightweight performance. Compared with conventional metals, titanium presents unique challenges during machining due to its high tensile strength, low thermal conductivity, and strong chemical reactivity at elevated temperatures.

Our Dongguan-based CNC machining facility focuses on custom titanium machining parts, providing reliable 5 axis CNC machining services for global OEM and ODM customers. From functional prototypes to stable batch production, we deliver titanium components that meet strict industrial requirements.

CNC Machining Capability Overview

All titanium parts are produced using full CNC machining processes, ensuring consistent dimensional accuracy and repeatability.

Our machining setup allows complex titanium parts to be completed in fewer setups, minimizing deformation and tolerance accumulation.

Machining Processes We Offer

To meet diverse design and application requirements, we support a wide range of machining processes:

These processes allow us to handle both simple geometric components and highly complex titanium structures with internal features and tight tolerances.

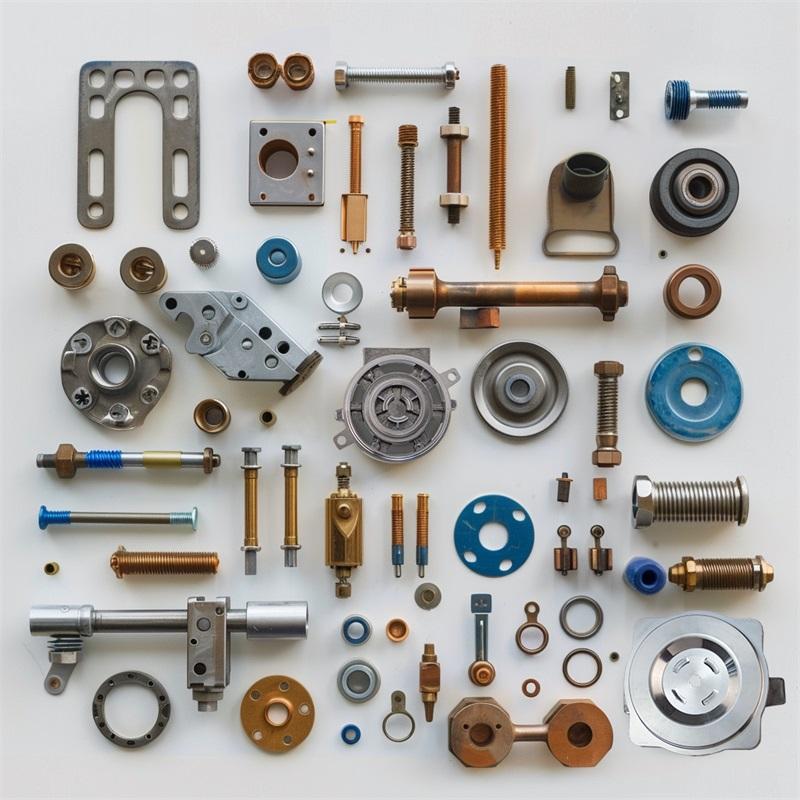

Titanium and Multi-Material Machining

While titanium machining is our core strength, we also work with multiple metals to support complete assemblies and system-level projects.

Supported Materials

Material selection is guided by mechanical performance, environmental exposure, weight considerations, and cost efficiency.

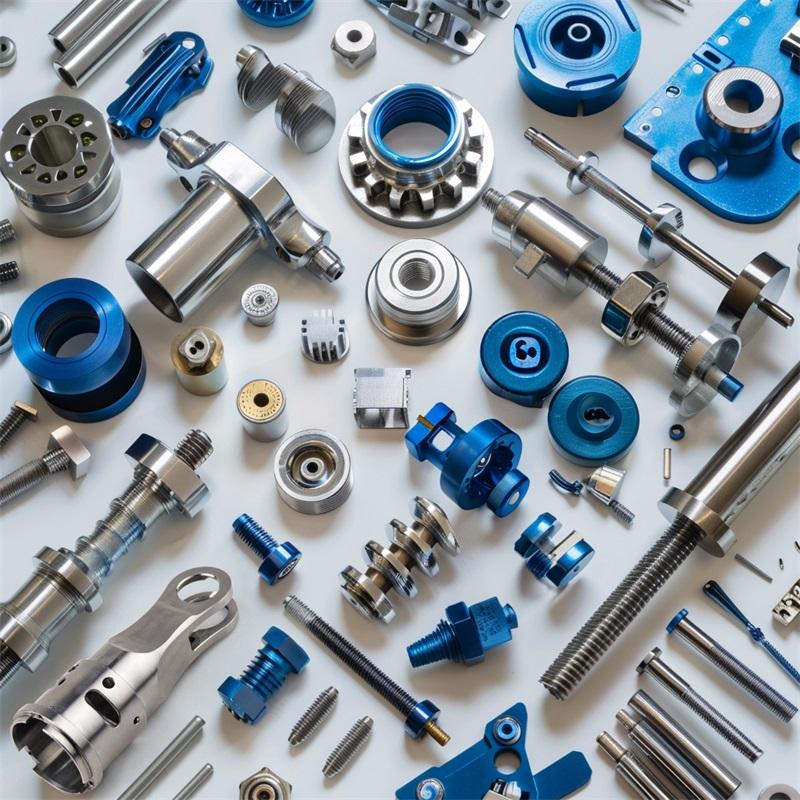

Typical Applications of Titanium Machining Parts

Our CNC machined titanium components are commonly used in:

Titanium is especially suitable for applications where corrosion resistance, fatigue strength, and long service life are critical.

Engineering & Production Workflow

Each titanium machining project follows a controlled manufacturing flow designed to reduce risk and ensure quality.

1. Design Evaluation

Customer drawings or samples are reviewed to analyze tolerances, geometry complexity, and machining feasibility.

2. Process Planning

Cutting strategies, tooling selection, and machining sequences are optimized specifically for titanium material behavior.

3. CNC Machining

Parts are machined using CNC and 5 axis equipment with strict control of cutting speed, feed rate, and heat generation.

4. Deburring & Edge Treatment

All sharp edges and burrs are removed to ensure safe handling and proper assembly.

5. Surface Finishing

Surface treatment is applied based on customer request and application needs.

6. Inspection & Verification

Dimensional checks ensure parts conform to drawings and specifications.

Surface Treatment Options

Surface treatment for titanium machining parts can be customized to meet functional or aesthetic requirements:

These treatments can enhance corrosion resistance, surface uniformity, or assembly compatibility.

Precision Control & Quality Assurance

Titanium machining requires strict control due to material sensitivity. Our quality focus includes:

Our machining experience allows us to maintain stable quality even for complex titanium components.

Packaging and Logistics

Packaging Method

Packaging Specifications

Shipping Options

International shipping is supported via:

We select shipping methods based on delivery time, destination, and customer preference.

OEM & ODM Titanium Machining Services

We support OEM and ODM titanium machining projects, providing flexible cooperation models:

Customers may provide full technical drawings or functional requirements only.

Advantages of Choosing Our Titanium Machining Service

Our location in Dongguan enables efficient supply chain coordination and competitive manufacturing costs.

Product Information Summary

CATEGORIES

LATEST NEWS

CONTACT US

Whatsapp: +8618998453346

Phone: +8618998453346

Tel: +8618998453346

Email: [email protected]

Addr: Room 302, Building D, COFCO Gonghua Project, Zone 20, Honglang Community, Xin'an Street, Bao'an District, Shenzhen City.