Tantalum CNC Turning Parts

Reliable Titanium Machining Services for Consistent CNC Part Production

- Product ID: Tantalum CNC Turning Parts

- Tel: +8618998453346

- WhatsApp: +8618998453346

- Tel: +8618998453346

- Email: [email protected]

- Time: 2025-06-23 19:28

- Price: 0

Standardized machining parameters

Fixed tooling and fixture strategies

Controlled machine setup procedures

Documented production workflows

CNC Machining: Yes

5 Axis CNC Machining: Supported

Micro Machining: Available

Production Machining: Supported

CNC Milling

CNC Turning

Precision Drilling and Threading

Broaching

Wire EDM

Laser Machining

Chemical / Etching Machining

Rapid Prototyping

Titanium (custom grade per project)

Aluminum

Stainless Steel

Steel Alloys

Brass

Bronze

Copper

Hardened Metals

Precious Metals

Metal processing machinery parts

Precision industrial components

Aerospace structural and connector parts

Medical equipment components

Automation and robotic assemblies

Automotive lightweight systems

Energy and marine equipment

Polishing

Sandblasting

Passivation

Anodizing (where applicable)

Custom surface finishes

Consistent machining conditions

Tool wear monitoring

Repeatable surface finish quality

Batch-to-batch dimensional stability

Individual polybag protection

Carton packaging for transport safety

Custom packaging options available

Selling Unit: Single item

Package Size: 33 × 10 × 5 cm

Gross Weight: 1.000 kg

DHL

UPS

FedEx

Drawing-based OEM manufacturing

ODM project cooperation

Prototype and pilot production

Stable batch and mass production

Custom branding and trademark support

Strong focus on batch consistency

Advanced CNC and 5 axis machining capability

Stable production workflows

Predictable delivery schedules

Experience supporting repeat international orders

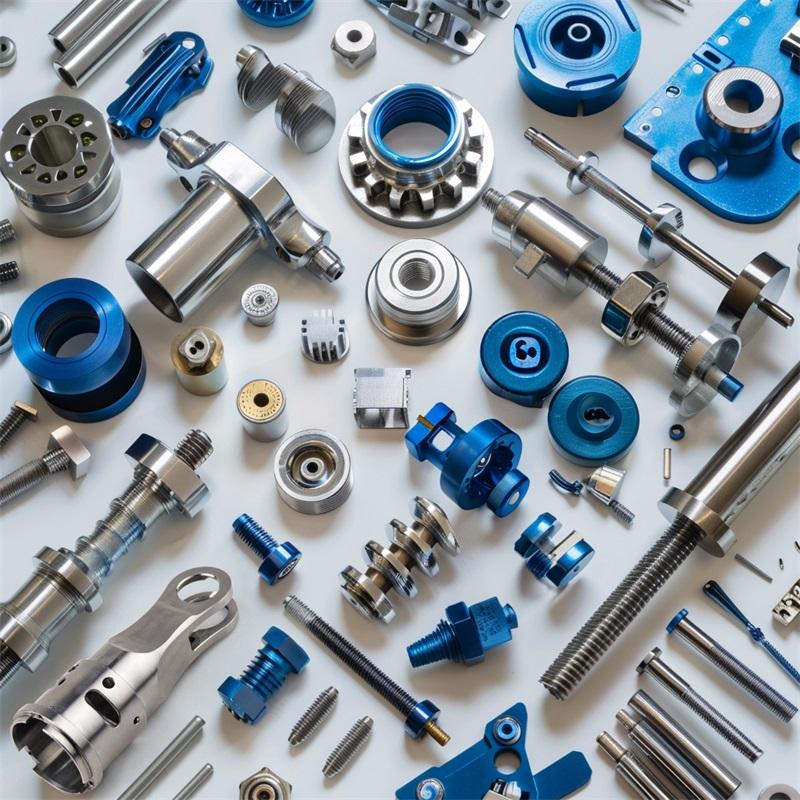

Product Name: Professional Precision CNC Machining Parts

Core Capability: Titanium Machining

Machining Method: CNC Machining, 5 Axis CNC

Micro Machining: Supported

Material: Customer’s Requirement

Process: CNC Machining + Deburring

Surface Treatment: As Requested

Service: OEM / ODM

Place of Origin: China

Application: Metal Processing Machinery Parts

Shipping: DHL / UPS / FedEx

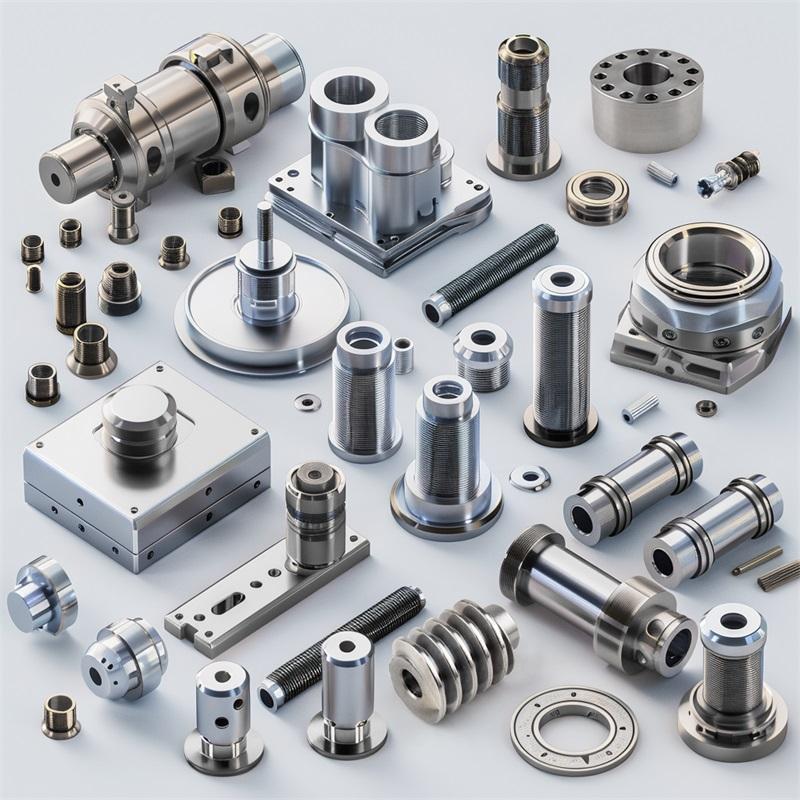

Titanium Machining from a Production Reliability Perspective

For industrial buyers, titanium machining is not only about achieving precision on a single part, but about maintaining consistent quality across repeated production cycles. Titanium’s physical properties make it an excellent material for demanding environments, yet these same characteristics introduce challenges when parts must be produced repeatedly with identical specifications.

Our CNC machining facility in Dongguan, China, provides reliable titanium machining services designed for customers who value batch consistency, stable lead times, and predictable manufacturing outcomes. By focusing on process control rather than one-off machining, we help customers reduce supply chain risk.

Managing Consistency in Titanium Machining

Titanium machining requires more disciplined process control than many common metals. Small variations in cutting conditions or tool performance can affect surface finish and dimensional accuracy.

To maintain consistency, our production approach emphasizes:

This allows us to deliver titanium components that remain consistent across prototypes, pilot runs, and full-scale production.

CNC & 5 Axis Machining Capability

Our equipment configuration supports both precision and repeatability:

5 axis CNC machining enables multi-face processing in a single setup, reducing positional deviation and improving batch uniformity.

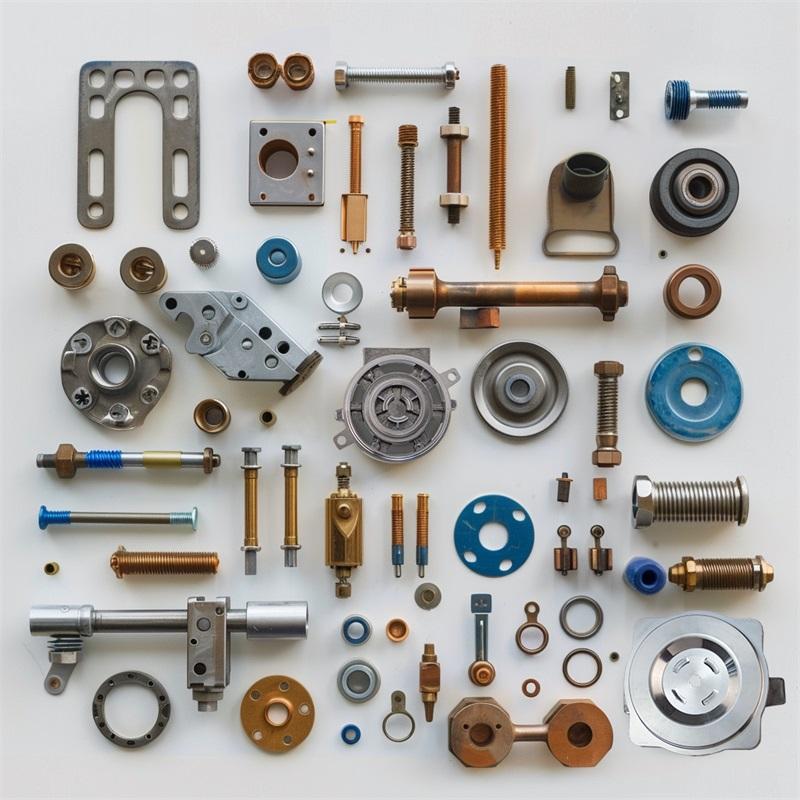

Machining Processes Used

We apply a combination of machining processes to meet different functional requirements:

These processes allow flexible production of both simple and complex titanium components.

Materials We Machine

Titanium machining is our core capability, supported by additional materials for assembly compatibility:

Material selection is aligned with performance requirements and long-term supply stability.

Industrial Applications Requiring Repeatability

Our titanium machining services support applications where consistency is critical:

These applications often require repeated orders with minimal variation between batches.

Production-Oriented Workflow

Our titanium machining workflow is structured to support ongoing production rather than isolated jobs.

Project Setup

Drawings and specifications are reviewed to define repeatable machining conditions.

Process Lock-In

Machining parameters and tooling selections are fixed once validated.

CNC Machining

Parts are produced under controlled, repeatable conditions.

Deburring & Functional Finishing

Edges and surfaces are processed to ensure safe assembly and handling.

Dimensional Verification

Key dimensions are checked to confirm batch consistency.

Surface Treatment Options

Surface treatments are applied according to functional requirements:

Surface treatments are standardized for repeat orders whenever possible.

Quality Assurance for Batch Production

Quality assurance focuses on process stability rather than inspection alone, including:

This approach supports long-term cooperation and supply reliability.

Packaging & International Delivery

Packaging Method

Package Information

Shipping Options

Logistics arrangements are optimized for repeat international shipments.

OEM & ODM Support for Long-Term Supply

We provide OEM and ODM titanium machining services designed for ongoing production needs:

This structure supports long-term procurement programs.

Why Production-Focused Buyers Work with Us

Our goal is to become a stable machining partner rather than a short-term supplier.

Product Information Summary

CATEGORIES

LATEST NEWS

CONTACT US

Whatsapp: +8618998453346

Phone: +8618998453346

Tel: +8618998453346

Email: [email protected]

Addr: Room 302, Building D, COFCO Gonghua Project, Zone 20, Honglang Community, Xin'an Street, Bao'an District, Shenzhen City.