Tantalum CNC Turning Parts

High-Precision Titanium Machining Parts – Custom 5 Axis CNC Machining Solutions from China

- Product ID: Tantalum CNC Turning Parts

- Tel: +8618998453346

- WhatsApp: +8618998453346

- Tel: +8618998453346

- Email: [email protected]

- Time: 2025-06-23 19:42

- Price: 0

Optimized cutting parameters

Stable CNC machine rigidity

Controlled heat generation

Precision tooling selection

CNC Machining: Yes

5 Axis CNC Machining: Available

Micro Machining: Supported

Custom Production: Supported

CNC Milling

CNC Turning

Drilling and Tapping

Broaching

Wire EDM

Laser Machining

Chemical / Etching Machining

Rapid Prototyping

Other Custom Machining Services

Titanium (custom grades per customer requirement)

Aluminum

Stainless Steel

Steel Alloys

Brass

Bronze

Copper

Hardened Metals

Precious Metals

Metal processing machinery parts

Precision industrial equipment

Aerospace structural and functional components

Medical device housings and connectors

Robotics and automation systems

Automotive lightweight components

Energy and marine equipment

Polishing

Sandblasting

Passivation

Anodizing (where applicable)

Customized surface finishes

Consistent dimensional accuracy

Stable surface finish quality

Burr-free edges

Repeatable batch performance

Individual polybag protection

Carton packaging for external protection

Custom packaging available if required

Selling Unit: Single item

Package Size: 33 × 10 × 5 cm

Gross Weight: 1.000 kg

DHL

UPS

FedEx

Drawing-based manufacturing

Prototype development

Small-batch trial production

Scaled mass production

Custom branding and trademark support

Specialized experience in titanium machining

Advanced CNC and 5 axis machining capability

Flexible customization and responsive communication

Stable quality control system

Export-oriented manufacturing experience

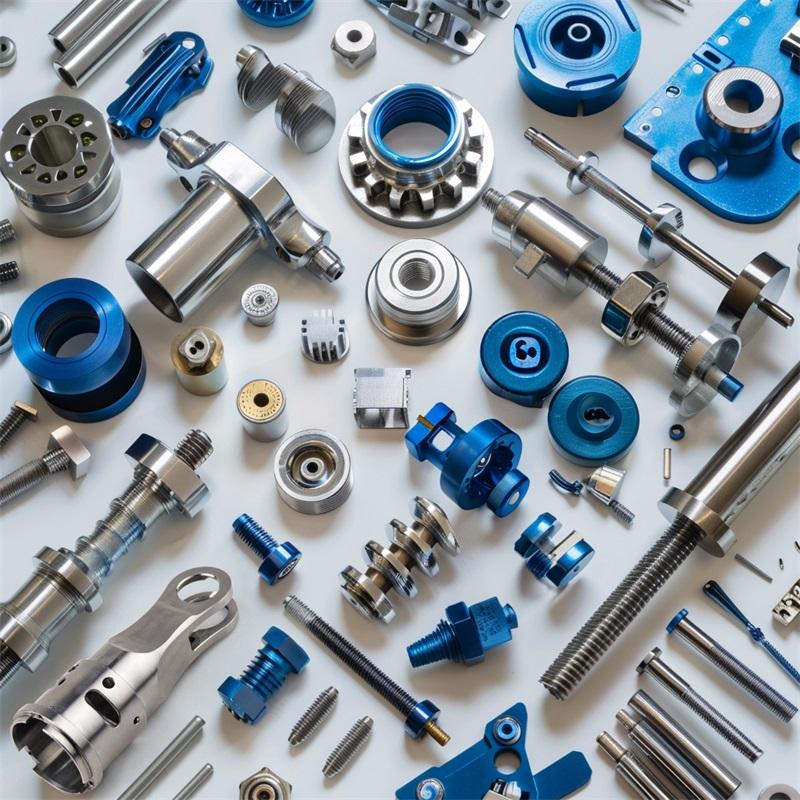

Product Name: Professional Precision CNC Machining Parts

Core Technology: Titanium Machining

Machining Type: CNC Machining, 5 Axis CNC

Micro Machining: Supported

Material: Customer’s Requirement

Process: CNC Machining + Deburring

Surface Treatment: Customer’s Request

Service: OEM / ODM

Place of Origin: China

Application: Metal Processing Machinery Parts

Shipping: DHL / UPS / FedEx/Ship

Overview of Our Titanium Machining Service

Titanium machining plays a critical role in modern manufacturing industries that require lightweight structures, high mechanical strength, and long-term corrosion resistance. Due to titanium’s material characteristics, producing high-quality titanium parts requires not only advanced CNC equipment, but also deep process knowledge and strict control during machining.

Our CNC machining facility specializes in custom titanium machining parts, offering 5 axis CNC machining services for customers worldwide. We support OEM and ODM projects across various industries, delivering precision-machined titanium components that meet demanding technical and performance standards.

Why Titanium Machining Requires Advanced CNC Capability

Titanium differs significantly from common metals such as aluminum or carbon steel. During machining, titanium generates concentrated heat at the cutting edge, which can accelerate tool wear and affect surface quality if not properly controlled.

To address these challenges, our titanium machining process focuses on:

With 5 axis CNC machining, complex titanium parts can be completed in fewer operations, improving accuracy and consistency.

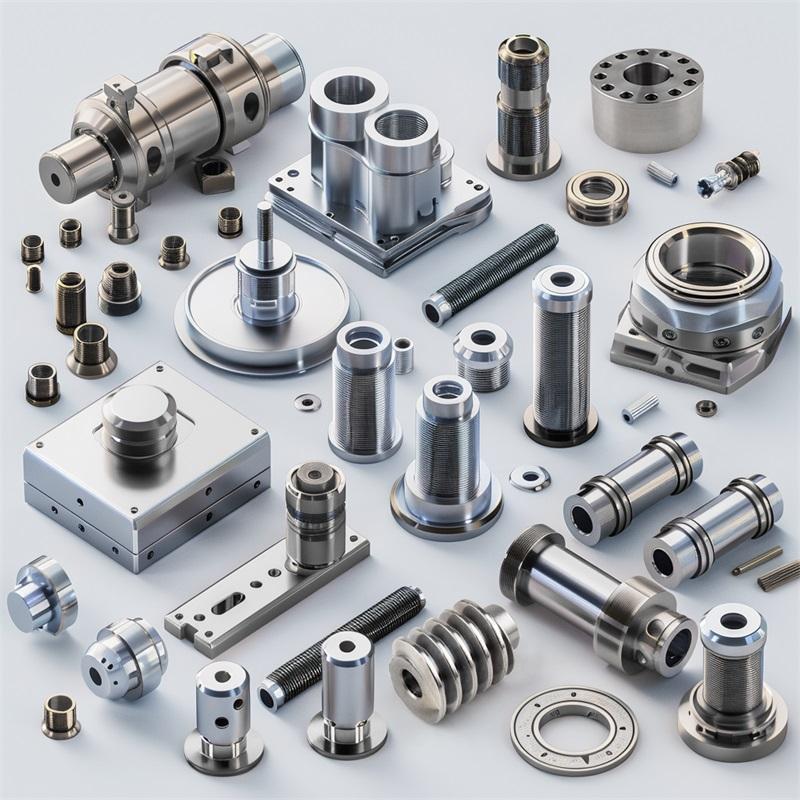

CNC Machining Capabilities

We provide full CNC machining services for titanium and other metals:

This capability allows us to manufacture both standard components and complex titanium parts with intricate geometries, tight tolerances, and fine surface requirements.

Machining Processes Available

To support different design requirements, we offer a wide range of machining processes:

By combining multiple processes, we can handle titanium components with internal features, thin walls, and complex profiles.

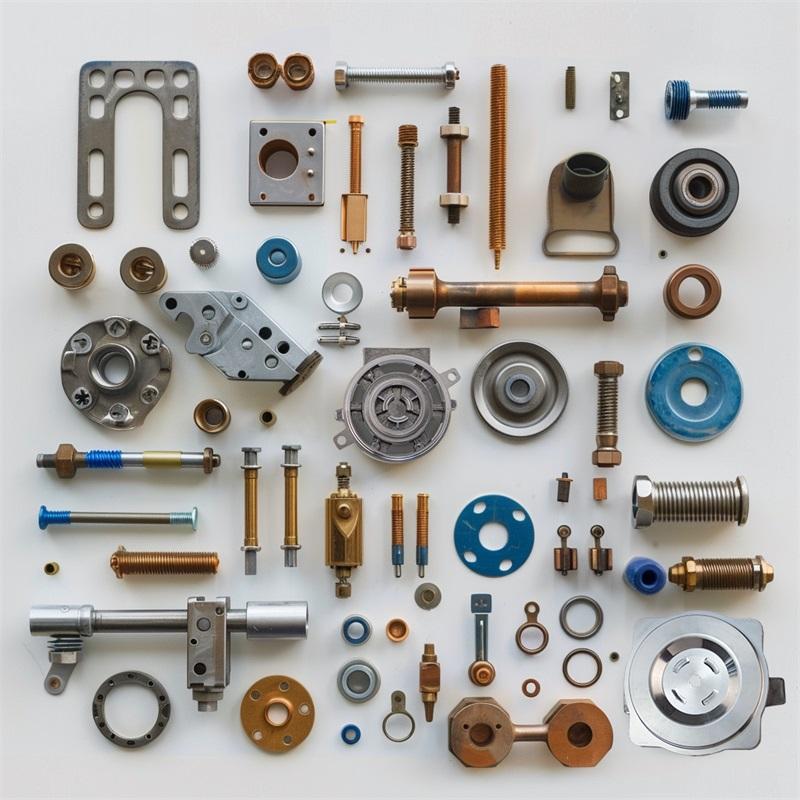

Titanium and Other Machinable Materials

Although titanium machining is our primary focus, we also machine various metals to support complete assemblies or mixed-material designs.

Supported Materials

Material selection is based on functional requirements, environmental exposure, mechanical performance, and cost targets.

Applications of CNC Machined Titanium Parts

Our titanium machining parts are widely used in:

Titanium’s resistance to corrosion and fatigue makes it ideal for harsh operating environments and long-life applications.

Manufacturing Workflow

Each titanium machining project follows a controlled production workflow to ensure quality and efficiency.

Engineering Review

Customer drawings or samples are analyzed to confirm dimensions, tolerances, and machinability.

Process Planning

Machining strategies are optimized to minimize deformation and improve tool life during titanium cutting.

CNC Machining

Parts are produced using CNC and 5 axis machining equipment under controlled parameters.

Deburring & Finishing

Edges and surfaces are treated to remove burrs and improve handling and assembly performance.

Quality Inspection

Dimensional checks are conducted to ensure compliance with drawings and specifications.

Surface Treatment Options

Surface treatments for titanium machining parts are available according to customer request, including:

Surface treatments can improve corrosion resistance, wear performance, or visual appearance.

Precision Control & Quality Focus

Precision is a key requirement in titanium machining. Our production focuses on:

Through controlled machining processes and experienced operators, we maintain stable quality across different production volumes.

Packaging and International Shipping

Packaging Method

Package Details

Shipping Options

We support international delivery via:

Shipping methods can be selected based on delivery time and destination.

OEM & ODM Titanium Machining Support

We provide flexible OEM and ODM titanium machining services, including:

Customers may supply full technical drawings or functional requirements only.

Advantages of Working with Our CNC Machining Factory

Our Dongguan location enables efficient production scheduling and competitive manufacturing costs.

Product Information Summary

CATEGORIES

LATEST NEWS

CONTACT US

Whatsapp: +8618998453346

Phone: +8618998453346

Tel: +8618998453346

Email: [email protected]

Addr: Room 302, Building D, COFCO Gonghua Project, Zone 20, Honglang Community, Xin'an Street, Bao'an District, Shenzhen City.