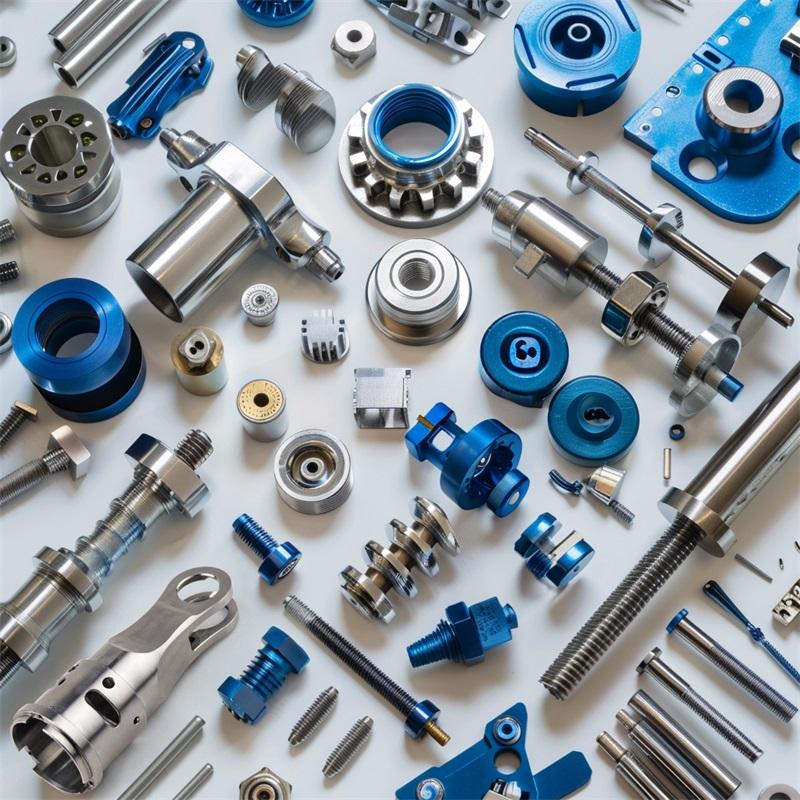

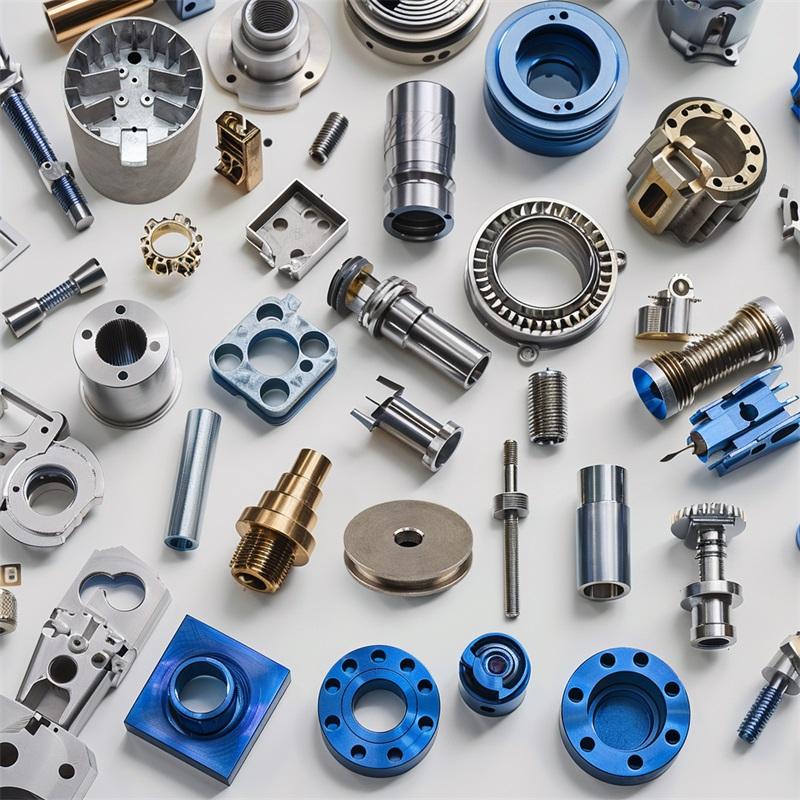

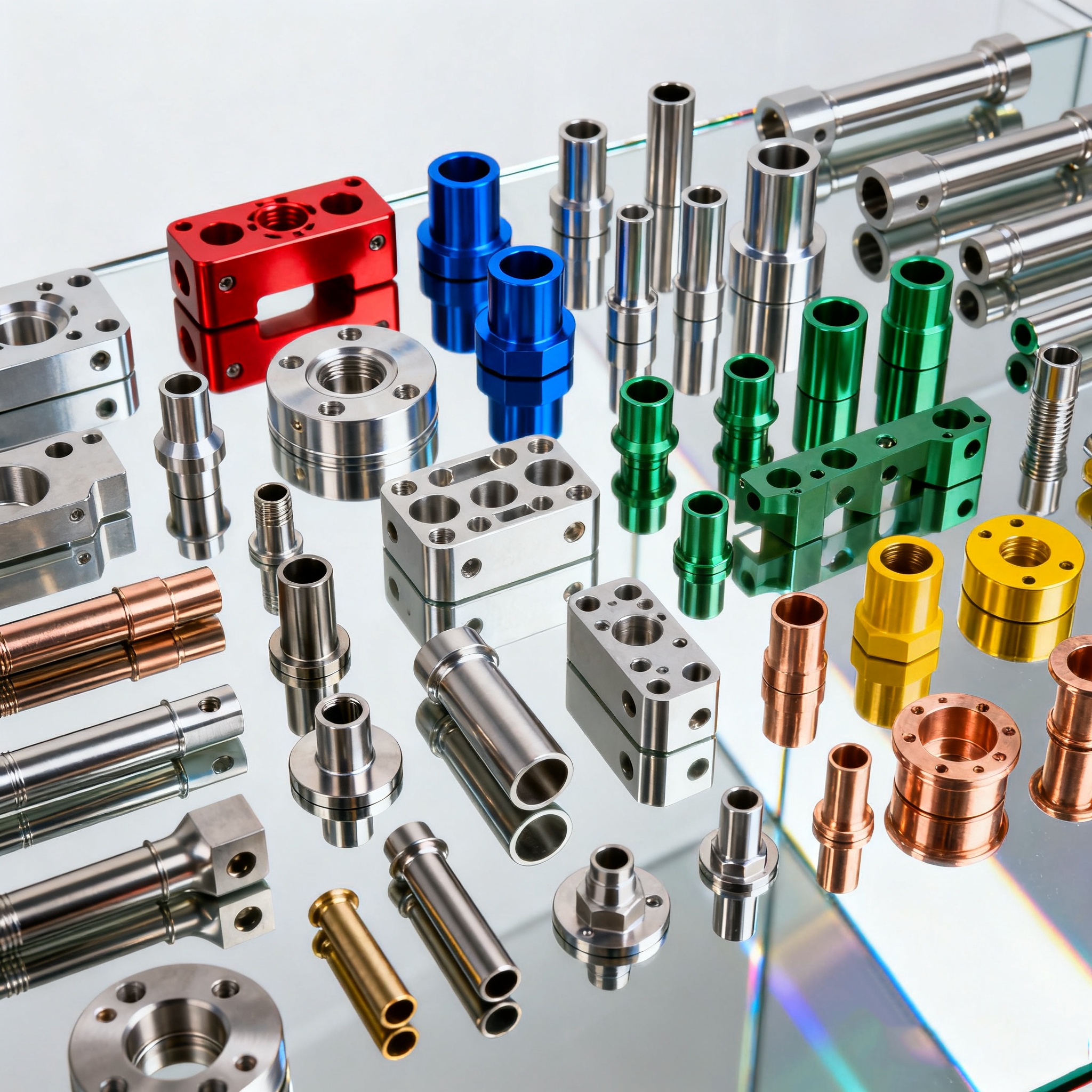

Titanium CNC Turning Parts

Titanium Machining for Medical Implants and Surgical Components

- Product ID: Titanium CNC Turning Parts

- Tel: +8618998453346

- WhatsApp: +8618998453346

- Tel: +8618998453346

- Email: [email protected]

- Time: 2024-08-18 18:17

- Price: 0

Heat generation affecting surface integrity

Tool wear during fine finishing operations

Maintaining dimensional stability on small, complex parts

Precision milling for implant profiles

Turning for cylindrical implant components

Drilling micro-holes for fixation and alignment

CMM inspection for dimensional accuracy

100% visual inspection

Gauge checks for critical features

Optimize implant designs for machinability

Ensure compliance with medical manufacturing requirements

Support prototyping and low-volume production

Orthopedic implants

Surgical instruments

Medical device components requiring high precision

Background: Medical Implant and Surgical Component Requirements

Background: Medical Implant and Surgical Component Requirements

Medical implants and surgical components demand the highest standards of precision, biocompatibility, and surface quality. Titanium is the preferred material due to its corrosion resistance, strength, and compatibility with the human body.

In this case, the customer required custom titanium components for medical implants and surgical devices. CNC titanium machining was selected to achieve tight tolerances, smooth surfaces, and consistent repeatability.

Material Selection and Titanium Machinability

Medical-grade titanium alloys were chosen for their proven performance in implant applications. However, titanium machinability challenges included:

Understanding the machinability of titanium alloys was essential to produce reliable medical components.

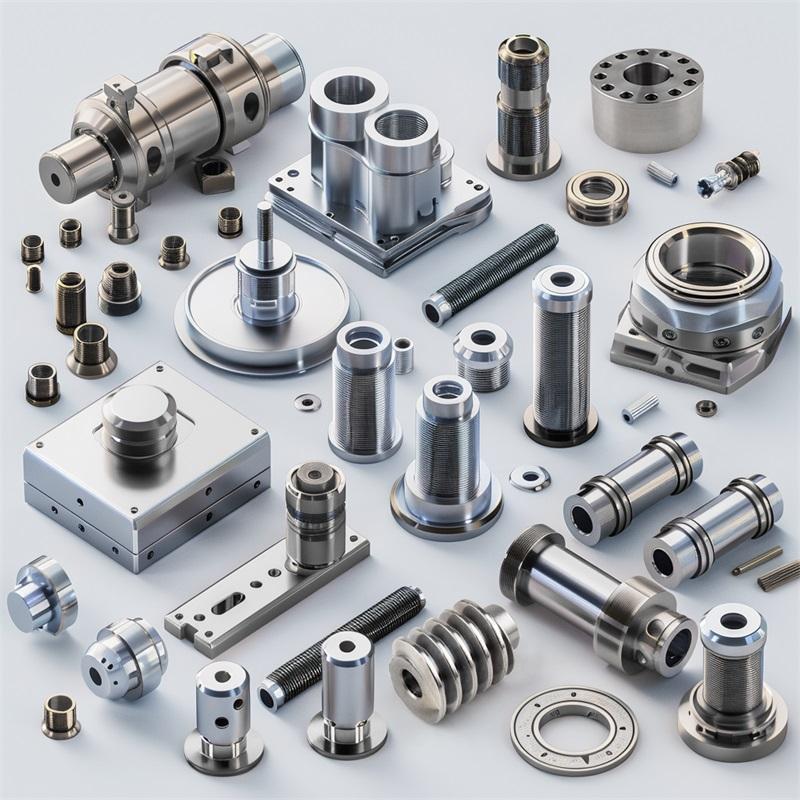

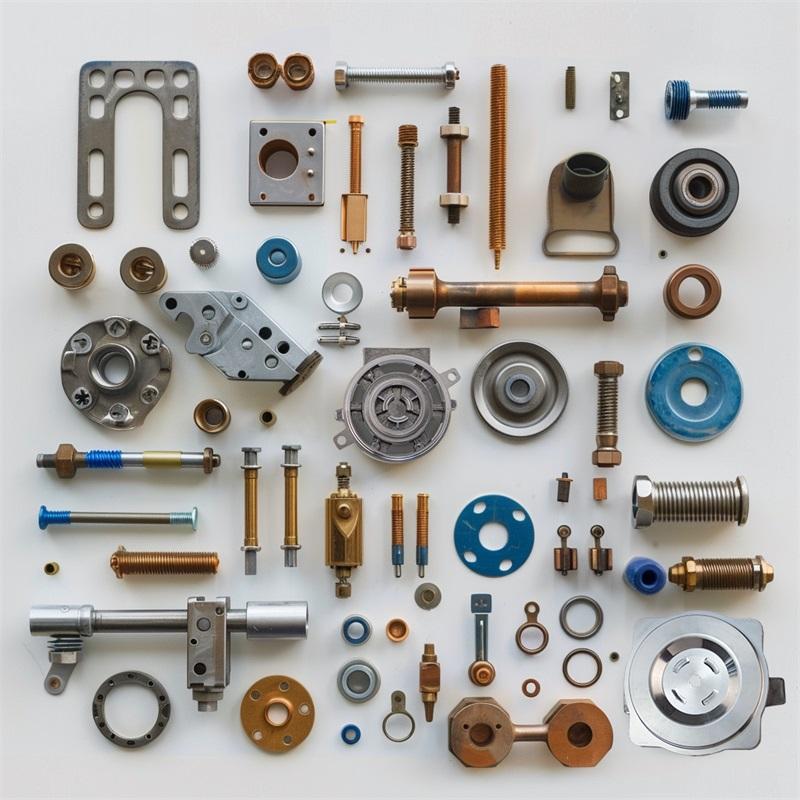

CNC Titanium Machining Process

CNC machining operations included:

Precision titanium machining ensured consistent dimensions and surface quality.

Surface Finish and Dimensional Accuracy

All critical dimensions were controlled within ±0.01 mm. Surface finishes were optimized to meet medical application requirements, reducing wear and improving long-term performance.

Inspection and Quality Control

Quality assurance processes included:

These inspection methods ensured machined titanium parts met medical industry standards.

OEM and Engineering Collaboration

Engineering teams worked closely with medical device manufacturers to:

CAD, CAM, and CAE tools were used, with support for STEP, DWG, DXF, IGS, STL, and PDF formats.

Applications in Medical Industry

Titanium machining is widely used for:

Titanium CNC parts provide durability, corrosion resistance, and biocompatibility.

Conclusion

This case demonstrates how CNC titanium machining delivers high-precision medical implants and surgical components. By addressing titanium machinability challenges and implementing strict inspection standards, reliable and accurate machined titanium parts were produced for medical applications.

CATEGORIES

LATEST NEWS

CONTACT US

Whatsapp: +8618998453346

Phone: +8618998453346

Tel: +8618998453346

Email: [email protected]

Addr: Room 302, Building D, COFCO Gonghua Project, Zone 20, Honglang Community, Xin'an Street, Bao'an District, Shenzhen City.