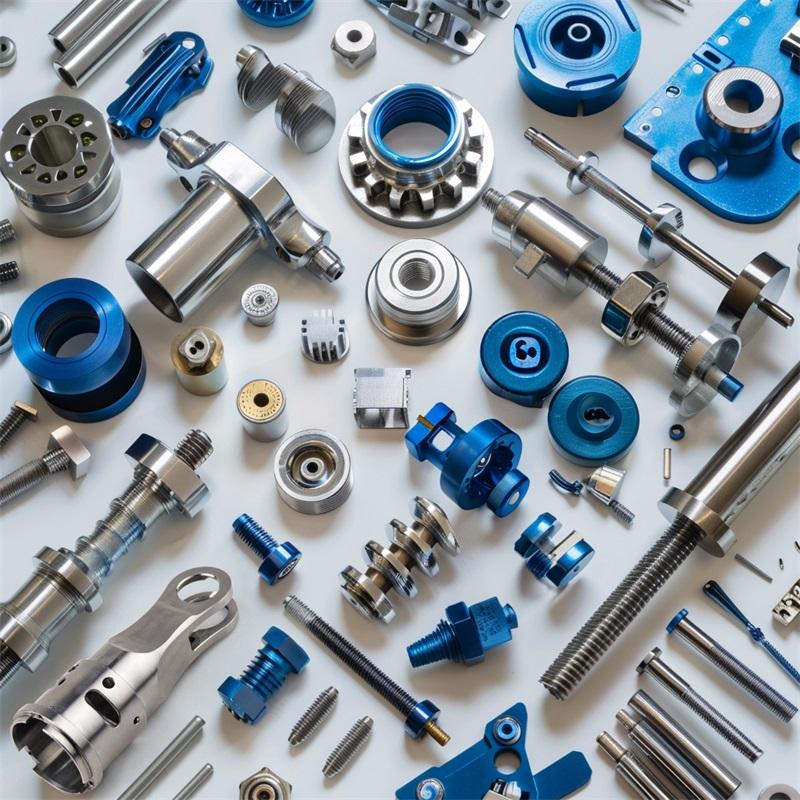

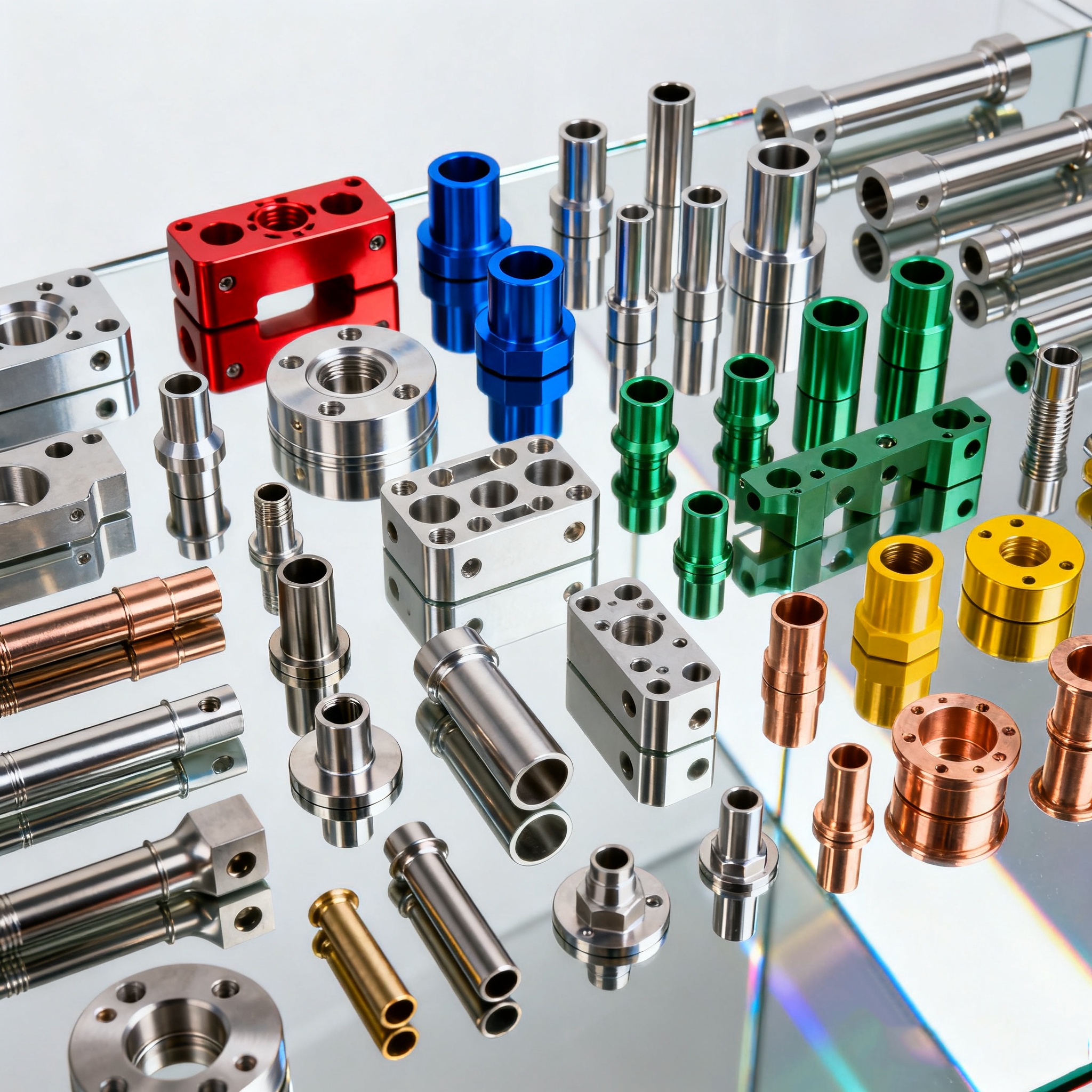

Titanium CNC Turning Parts

Titanium Sinker EDM Machining for Aerospace and Medical Components

- Product ID: Titanium CNC Turning Parts

- Tel: +8618998453346

- WhatsApp: +8618998453346

- Tel: +8618998453346

- Email: [email protected]

- Time: 2024-08-15 17:00

- Price: 0

Poor thermal conductivity leading to localized heat

Tool wear in conventional machining

Maintaining tight tolerances in complex cavities

Machining internal cavities and pockets

Maintaining fine features with precise electrode paths

Controlling material removal rates to reduce thermal impact

Face milling for reference surfaces

Drilling and tapping assembly holes

Milling external geometries and mounting features

CMM measurement of cavities and external features

Gauge verification of critical dimensions

100% visual inspection

Optimize EDM electrode design and machining parameters

Plan integrated EDM and CNC sequences

Validate prototypes before production

Aerospace precision cavities and brackets

Medical implant cavities and surgical device parts

Industrial assemblies with intricate internal geometries

Background: Sinker EDM Requirements

Aerospace and medical components often feature complex cavities, intricate geometries, and fine details that are difficult to machine using conventional methods. Sinker EDM (Electrical Discharge Machining) provides a precise, low-force solution for such titanium parts.

In this case, the customer required titanium components with intricate cavities for aerospace assemblies and medical devices. Sinker EDM titanium machining was selected to achieve high accuracy without inducing mechanical stress.

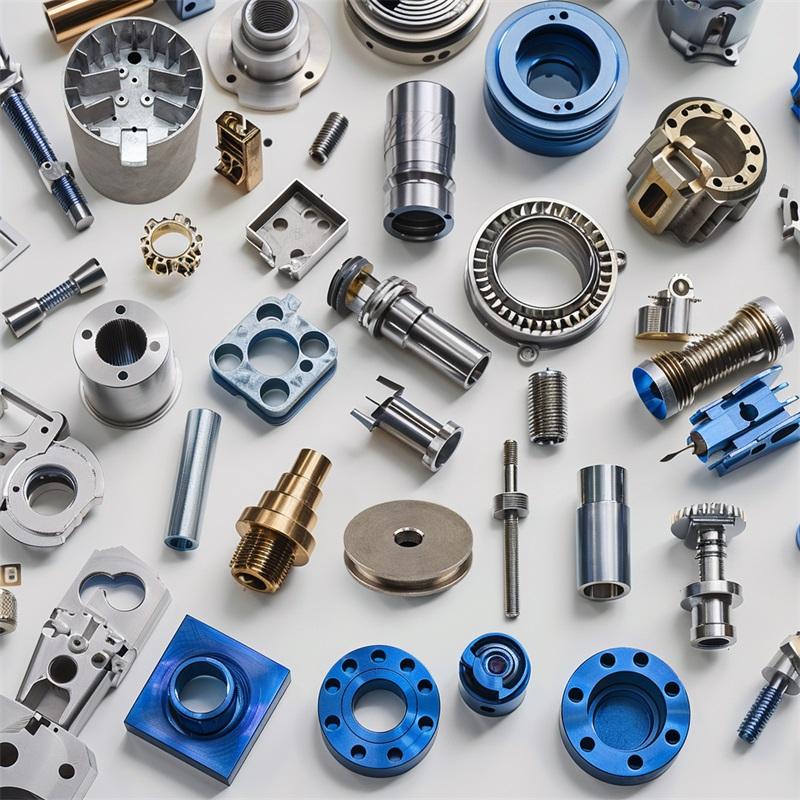

Material Selection and Titanium Machinability

Titanium alloys were chosen for their high strength, corrosion resistance, and stability under demanding conditions. Machinability challenges included:

EDM titanium machining eliminates cutting forces, making it ideal for precision cavities and fragile structures.

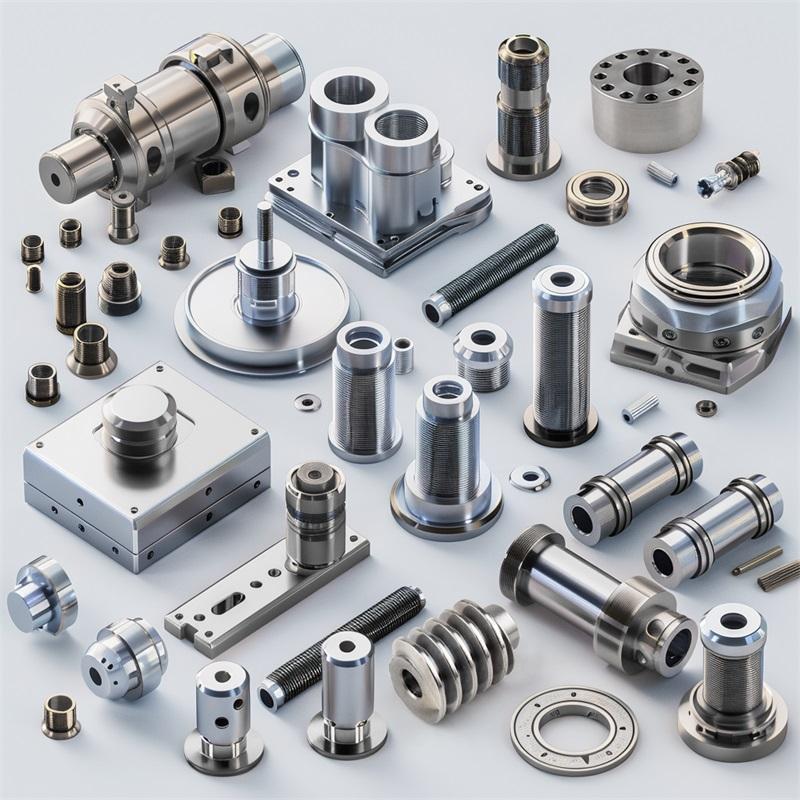

Sinker EDM Titanium Machining Process

Sinker EDM operations included:

Titanium sinker EDM provided repeatable accuracy and excellent surface quality for critical components.

Integration with CNC Titanium Machining

After sinker EDM, CNC titanium machining was applied to:

This hybrid approach ensured full functional integrity of machined titanium parts.

Dimensional Accuracy and Surface Quality

All critical dimensions were maintained within ±0.01 mm tolerance. Surface finishes were optimized for aerospace and medical standards, providing smooth cavities and clean edges.

Inspection and Quality Assurance

Inspection methods included:

These steps ensured all machined titanium parts met aerospace and medical quality standards.

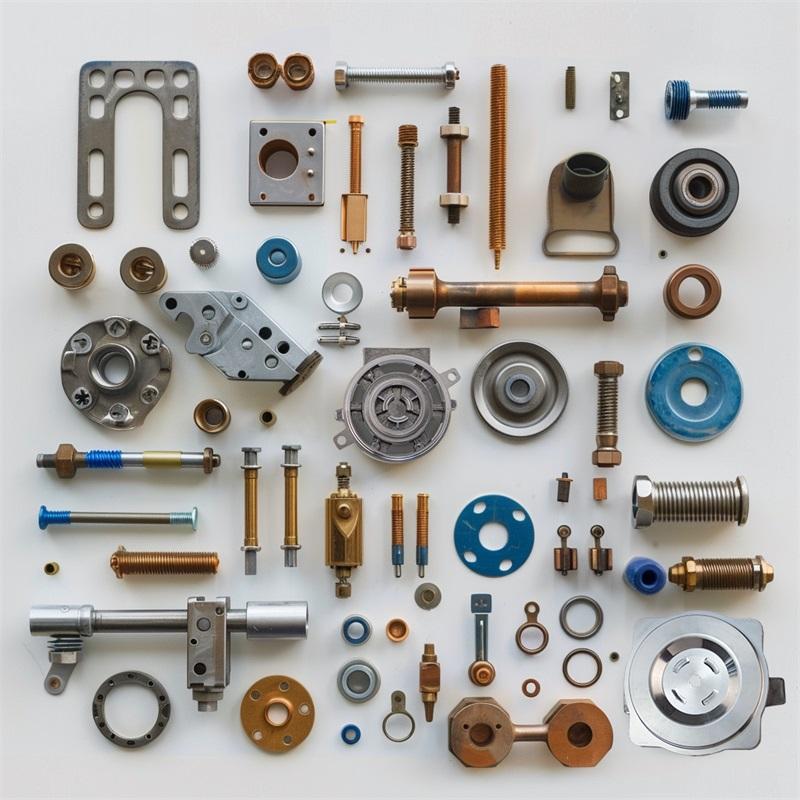

OEM and Engineering Collaboration

Engineering teams collaborated to:

Supported CAD, CAM, and CAE tools included STEP, DWG, DXF, IGS, STL, and PDF formats.

Applications of Sinker EDM Titanium Components

Titanium sinker EDM machining is widely used for:

This approach enables highly accurate titanium parts where conventional machining is insufficient.

Conclusion

This case demonstrates how titanium sinker EDM machining combined with CNC titanium machining produces precise and reliable aerospace and medical components. By addressing titanium machinability challenges and integrating inspection protocols, high-quality machined titanium parts were delivered for complex applications.

CATEGORIES

LATEST NEWS

CONTACT US

Whatsapp: +8618998453346

Phone: +8618998453346

Tel: +8618998453346

Email: [email protected]

Addr: Room 302, Building D, COFCO Gonghua Project, Zone 20, Honglang Community, Xin'an Street, Bao'an District, Shenzhen City.