English

Precision CNC Machining of Titanium and Nickel Alloys in China

Writer:admin Time:2025-05-30 01:01 Browse:℃

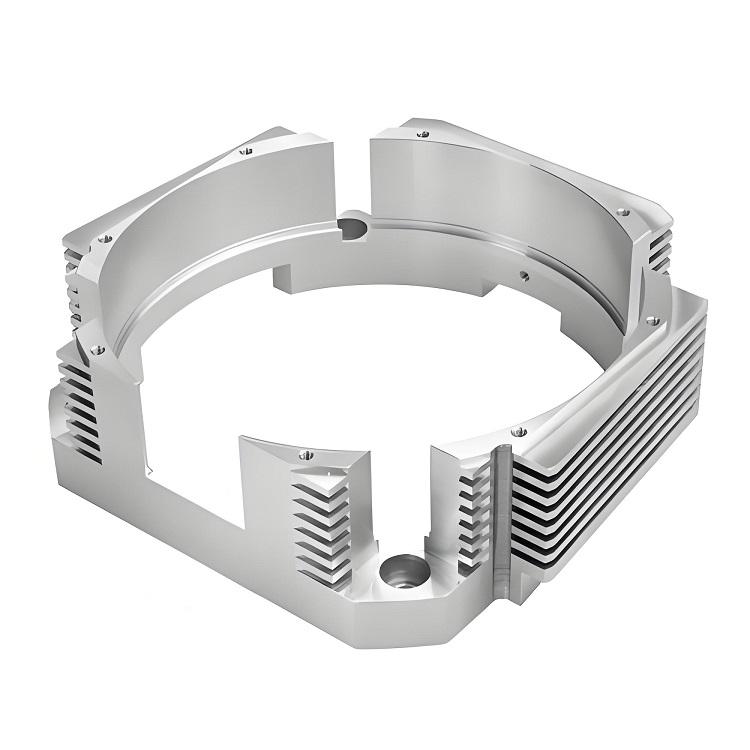

Machining titanium alloys (e.g., Ti-6Al-4V) and nickel superalloys (e.g., Inconel 718, Hastelloy) requires more than basic CNC skills. These materials are foundational in aerospace, medical, energy, and high-performance industrial applications, where the combination of strength, corrosion resistance, and heat tolerance demands careful process planning and precision execution.

Launching a precision CNC machining initiative — whether internal to your organization or as a sourcing strategy in China — involves multiple stages: material understanding, equipment selection, tooling strategy, process planning, quality assurance, supplier evaluation, and cost management.

This article walks through the entire journey from initial planning to execution, with six data tables of real reference metrics to help you benchmark readiness and make informed choices.

For deeper production insights, case studies, and machining strategies used in real factory environments with exotic materials, resources such as https://www.eadetech.com share valuable engineering perspective and applied examples.

1. Understand Material Characteristics First

Before machining begins, knowing why titanium and nickel alloys are challenging is critical.

Table 1: Material Characteristics Affecting Machining

| Material | Thermal Conductivity (W/m·K) | Elastic Modulus (GPa) | Hardness (HRC) | Tendency to Work Harden |

|---|---|---|---|---|

| Ti-6Al-4V | ~7–21 | ~110 | ~35–40 | Moderate |

| Ti-6Al-4V ELI | ~7–21 | ~110 | ~35–40 | Moderate |

| Inconel 718 | ~11–15 | ~200 | ~30–40 | High |

| Hastelloy | ~9–12 | ~204 | ~28–38 | High |

| 17-4 PH SS | ~14–16 | ~200 | ~28–32 | Moderate |

Key Insights:

Low thermal conductivity concentrates heat near the cut, accelerating tool wear.

High elastic modulus means parts resist deformation, but thin sections may flex under load.

Work hardening — especially in nickel alloys — demands optimized feeds to avoid surface strengthening.

2. Plan for Precision: Tolerance and Surface Quality

Precision machining is not just about shape — it’s about repeatable accuracy and surface integrity.

Table 2: Tolerance & Surface Finish Expectations

| Precision Level | Tolerance | Surface Roughness (Ra) | Typical Application |

|---|---|---|---|

| Commercial Standard | ±0.05 mm | ≤1.6 µm | Non-critical components |

| Precision | ±0.02 mm | ≤1.0 µm | Medium-tolerance parts |

| High Precision | ±0.01 mm | ≤0.8 µm | Aerospace/medical components |

| Ultra Precision | ≤±0.005 mm | ≤0.4 µm | Implants, high-performance seals |

Setting clear tolerance bands early prevents costly redesigns and repeated iterations.

3. Select the Right CNC Equipment

Precision machining of titanium and nickel alloys requires CNC platforms with capabilities beyond basic milling.

Table 3: CNC Machine Attributes for Precision Special Materials

| Feature | Why It Matters | Typical Specification |

|---|---|---|

| 5-Axis Capability | Complex geometry | Simultaneous multi-axis |

| Thermal Compensation | Dimensional stability | Active or built-in |

| High-Rigidity Frame | Vibration reduction | Cast/box-way design |

| High-Pressure Coolant | Heat & chip control | ≥70 bar |

| Through-Spindle Coolant | Deep pocket machining | Yes |

| In-Process Probing | Real-time correction | Optional but valuable |

Multi-axis CNC reduces setups and improves geometric conformity.

Thermal compensation addresses drift caused by heat during long cycles.

Without these features, achieving precision tolerances reliably on difficult alloys is challenging.

4. Tooling: What You Need for Hard Materials

Tool selection drives both performance and cost, especially when machining reactive alloys.

Table 4: Tooling Options & Typical Uses

| Tool Type | Best For | Advantages | Notes |

|---|---|---|---|

| Coated Carbide End Mills | Rough & semi-finish | Good heat & wear resistance | Baseline tooling |

| High Helix Mills | Thin walls & cavities | Enhanced chip evacuation | Preferred where access allows |

| Ball/Radius End Mills | Fine finishing | Smooth surface and contouring | Essential for tight tolerances |

| PCD / CBN Tools | Abrasive operations | Extremely wear-resistant | Higher cost |

| Ceramic Tools | High temp cuts | High hardness retention | Best for nickel alloys |

Best Practice: Tool geometries with positive rake angles and polished flutes help minimize adhesion and burr formation.

5. Establish Machining Parameters and Strategies

Correct cutting parameters are essential for material integrity and tolerance adherence.

Table 5: Reference Machining Parameters for Precision Titanium and Nickel Alloy Machining

| Operation | Material | Cutting Speed (m/min) | Feed per Tooth (mm) | Axial Depth (mm) | Engagement Strategy |

|---|---|---|---|---|---|

| Roughing | Ti-6Al-4V | 20–40 | 0.08–0.15 | 0.5–1.5 | Low radial engagement |

| Semi-finish | Ti-6Al-4V | 35–55 | 0.05–0.10 | 0.3–0.8 | Constant engagement |

| Finish | Ti-6Al-4V | 50–80 | 0.02–0.05 | 0.2–0.6 | Smooth path control |

| Roughing | Inconel 718 | 15–30 | 0.06–0.12 | 0.5–1.2 | Reduced chip load |

| Semi-finish | Inconel 718 | 25–45 | 0.04–0.08 | 0.3–0.8 | Adaptive milling |

| Finish | Inconel 718 | 40–60 | 0.02–0.05 | 0.15–0.4 | Light finishing passes |

Key Notes:

Lower cutting speeds reduce heat buildup in titanium.

Lower feed per tooth combined with shallow depths helps minimize springback and stress.

Further optimization may involve trochoidal milling, adaptive feed strategies, and CAM simulation.

6. Fixture Design and Workholding Best Practices

Holding parts securely, without inducing stress or deflection, is vital when machining hard materials.

Table 6: Fixture Strategies and Their Use Cases

| Workholding Method | Best Use | Advantages | Considerations |

|---|---|---|---|

| Soft Jaws | Prismatic parts | Even clamping pressure | Requires custom setup |

| Vacuum Fixtures | Flat thin panels | Minimal distortion | Needs sealing surface |

| Internal Mandrels | Tubular parts | Prevents internal flexing | Custom engineered |

| Modular Clamp Systems | Mixed geometry | Adjustable and repeatable | Higher initial setup |

| Support Fixtures | Thin walls | Reduces vibration | Must not restrict coolant |

Fixtures must be designed to support thin walls and control clamping force so that machining forces do not distort parts.

7. Quality Assurance and Inspection Infrastructure

Precision machining requires rigorous inspection throughout the process.

Inspection Tools & What They Achieve

Coordinate Measuring Machine (CMM): Dimensional verification

In-Process Probing: Detect tool and part drift

Laser Scanning: Full surface comparison

Surface Profilometry: Confirm Ra and surface integrity

Inspection is not a “final step”; it should be part of a process chain from first article to batch verification.

8. Supplier Evaluation: How to Choose a Partner in China

When sourcing CNC machining services for these materials in China, evaluate suppliers against these criteria:

Machine and equipment transparency

Quality certifications and documentation

Historical precision capability

Inspection and metrology investments

Tooling and process strategy

Communication and engineering support

Transparent cost breakdowns

Lead time and scheduling capabilities

Using a scoring method (e.g., capability, quality, price, communication) can help you objectively compare options.

An experienced supplier should also be able to provide reference cases, first article inspection (FAI) packages, and process route cards.

9. Understanding Cost Structure

Cost is influenced by multiple factors. When evaluating quotes, make sure to understand:

Material costs (expensive exotic alloys)

Machine time (special materials take longer to cut)

Tooling and consumables

Inspection costs

Setup and programming effort

Scrap risk and quality risk buffers

Clear cost breakdowns help you avoid surprises.

10. Communication and Contract Negotiation

Good communication sets expectations clearly and reduces risk.

Provide detailed CAD with GD&T

Specify tolerances and surface finish requirements

Establish inspection requirements

Define documentation standards (FAI, process flow, SPC)

Negotiation should include risk allocation, rework allowance, and warranty terms

A structured contract with clear deliverables improves project predictability.

11. Pilot Runs and Process Validation

Before full production:

Pilot machining runs

First article inspection

Process capability studies (Cp/Cpk)

Tool life tracking

Thermal and distortion analysis

These ensure that the manufacturing plan is validated and repeatable.

12. Continuous Improvement and Feedback Integration

Good factories treat each project as a learning opportunity. Best practices include:

Post-production review

Tooling optimization based on data

Virtual simulation updates

Supplier scorecards and quality audits

Collaborative design improvements

Feedback loops lead to cost savings and better precision over time.

13. Common Challenges and How to Overcome Them

Challenge: Warping and Distortion

Solution: Balanced toolpaths, symmetric machining, thermal control

Challenge: Tool Wear

Solution: High-performance tooling, predictive tool change based on data

Challenge: Surface Integrity

Solution: Optimized feeds, coolant strategy, finishing passes

Understanding causes and mitigation strategies leads to stable processes.

14. Real-World Application Examples

Example A – Aerospace Structural Bracket

Material: Ti-6Al-4V

Tolerance: ±0.01 mm

Solutions: 5-axis CNC, adaptive milling, high-pressure coolant

Example B – Industrial Burner Nozzle

Material: Inconel 718

Tolerance: ±0.02 mm

Solutions: Rigid fixturing, trochoidal toolpaths, exhaustive inspection

These contextual examples show how strategy and execution determine success.

For detailed applied case studies and engineering insights in precision machining of exotic materials, many engineers and manufacturing teams consult operational examples at https://www.eadetech.com.

15. Conclusion

Precision CNC machining of titanium and nickel alloys is challenging but achievable with the right planning and execution:

✔ Understand material behavior

✔ Choose appropriate CNC platforms

✔ Design fixtures for stability

✔ Set realistic tolerances and inspection plans

✔ Evaluate suppliers holistically

✔ Use structured cost frameworks

✔ Validate processes before full production

✔ Collaborate and improve continuously

By following these steps and leveraging structured supplier evaluations, you’ll be well-positioned to launch high-precision CNC machining initiatives in China that deliver quality, repeatability, and performance.

CATEGORIES

LATEST NEWS

CONTACT US

Whatsapp: +8618998453346

Phone: +8618998453346

Tel: +8618998453346

Email: [email protected]

Addr: Room 302, Building D, COFCO Gonghua Project, Zone 20, Honglang Community, Xin'an Street, Bao'an District, Shenzhen City.